Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

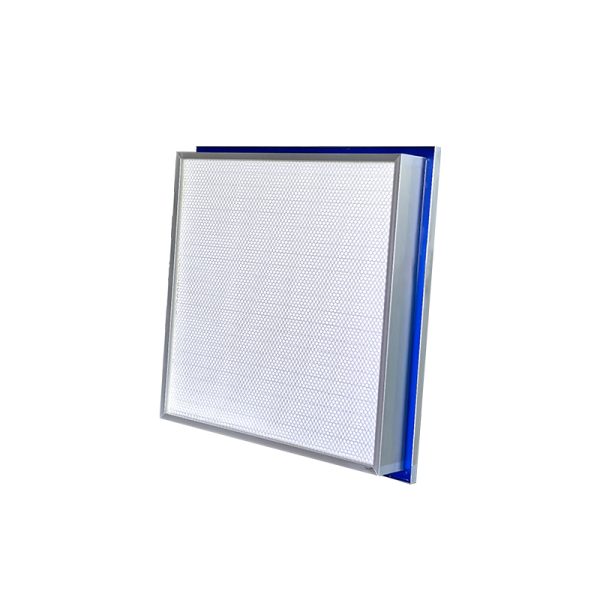

GMP Pass HEPA Filter

A HEPA filter is a core component of an air conditioning purification system. It is primarily used in constant temperature and humidity air conditioners, central air conditioners, and modular air conditioner terminals.

Table of Contents

What is a HEPA filter?

A HEPA filter is a core component of an air conditioning purification system. It is primarily used in constant temperature and humidity air conditioners, central air conditioners, and modular air conditioner terminals. It intercepts dust particles in the air and ensures cleanliness at the air outlet. Its core functions include physical filtration mechanisms such as interception, diffusion, inertia, and electrostatic adsorption, effectively capturing particles between 0.1 and 0.3 microns.

Designed with materials such as glass fiber, chemical fiber, and an aluminum alloy frame, this filter is particularly sui

table for high-purity environments due to its compact size, low resistance,

and uniform dust holding capacity. Filtration efficiency is affected by filter media performance, initial resistance, and operating air volume, requiring pre-filtration to extend its service life. According to GB standards, domestic HEPA filters are classified into four sodium flame efficiency categories: ≥99.9% (Grade A) to ≥99.999% (Grade D). Equipment maintenance requires regular monitoring of resistance changes. Replacement is required when the final resistance reaches twice the initial resistance or when efficiency drops to 85%. The typical service life is 3-5 years, and it requires an F8 pre-filter for optimal performance.

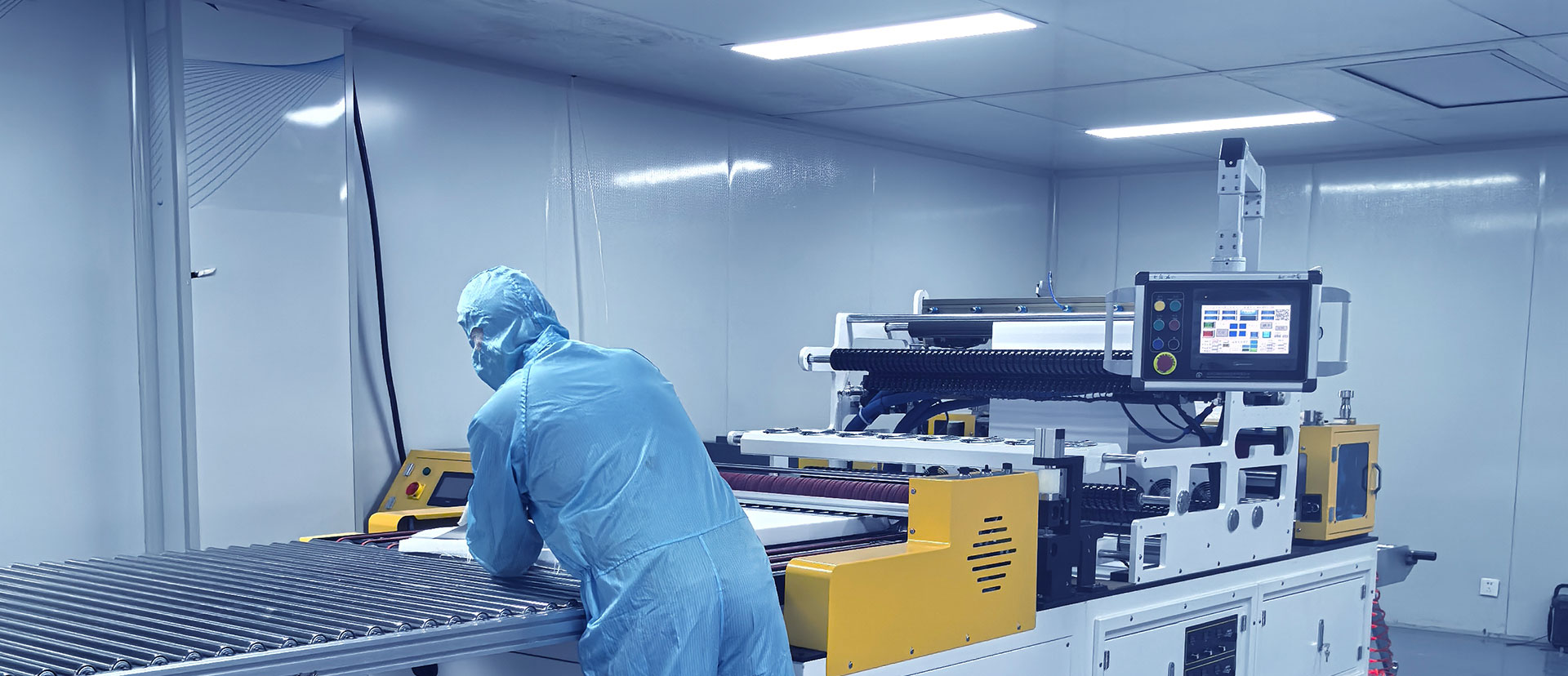

How are HEPA filters manufactured?

A.Frame Material

Mostly aluminum alloy or stainless steel (corrosion-resistant, suitable for cleanrooms). Precision bending, welding, or stamping are used to

ensure dimensional tolerances of

≤0.5mm and perpendicularity to the frame. Sealant: Polyurethane sealant (hig

hly elastic, temperature-resistant from -30℃ to 80℃) or silicone rubber (higher temperature resistance, suitable for high-temperature environments) is used to ensure tight adhesion to the filter paper and frame.

B.Filter Paper Pleating (Key Process)

To maximize filtration area, filter paper must be processed into uniform pleats. This is the core process of HEPA filters: Pleat depth (typically 45-65mm) and spacing (2-5mm) are designed based on airflow and resistance requirements. The number of pleats is calculated based on the filter paper area and frame dimensions (e.g., a 1220*610mm filter has approximately 300-500 pleats). Continuous pleats are pressed into the filter paper using a precision mold. The machine monitors the pleat depth and spacing in real time to ensure uniformity (tolerance ≤0.2mm).

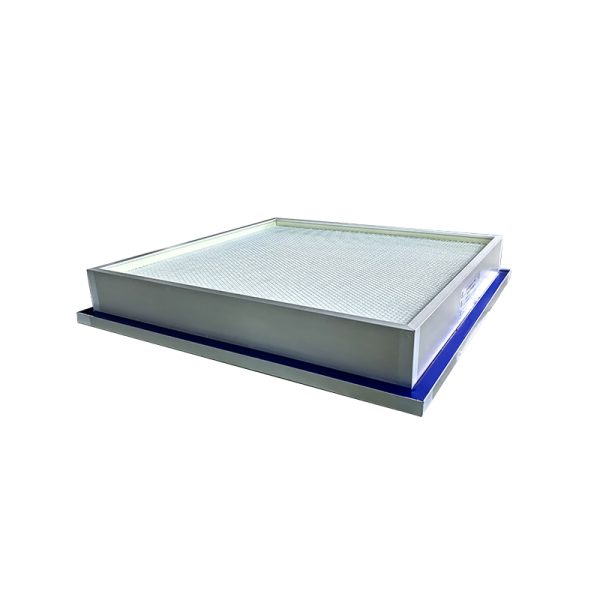

C.Filter Paper and Frame Assembly

Secure the pleated filter paper into the outer frame. Carefully place the pleated filter paper into the outer frame, ensuring the edges of the filter paper are completely aligned with the inner edge of the outer frame without any deviation or fold deformation. Apply an even layer of PU sealant (1-2mm thick) to the outer frame. Use a clamp to press the filter paper and outer frame together. Allow to stand at 25-30℃ for 4-8 hours to ensure the sealant is completely cured and forms a seamless seal.

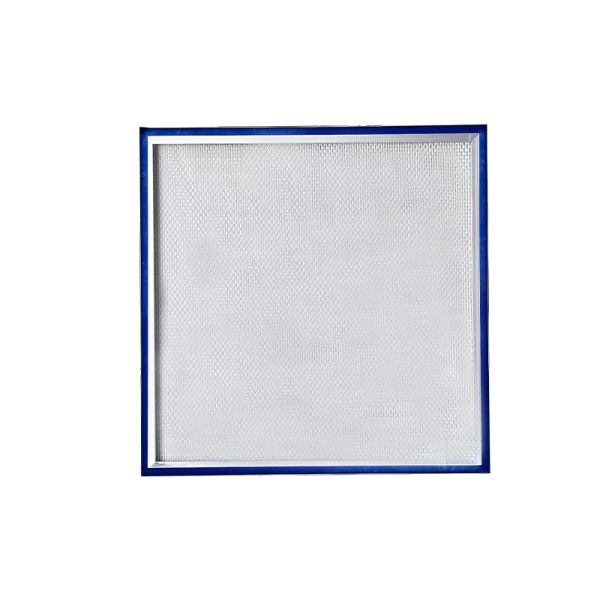

Application of HEPA Filters

High-efficiency air filters are widely used in the terminal air supply of air conditioners in cleanrooms in industries such as optical electronics, LCD manufacturing, biomedicine, precision instruments, beverages and food, and PCB printing. Both high-efficiency and ultra-high-efficiency filters are used at the end of cleanrooms.

Technical Specifications of HEPAFilters

The performance evaluation of high-efficiency air filters (HEPA) is primarily based on international standards, and different standards have different grading methods for filtration efficiency:

EN 1822 (Europe): Using the MPPS (Most Penetrating Particle Size) test method, filters are classified into grades H10-H14. Grade H13 requires a retention rate of ≥95% for particles 0.3μm, and grade H14 requires a retention rate of ≥99.995

EN 1822 (Europe): Using the MPPS (Most Penetrating Particle Size) test method, filters are classified into grades H10-H14. Grade H13 requires a retention rate of ≥95% for particles 0.3μm, and grade H14 requires a retention rate of ≥99.995- % for particles 0.3μm.

- GB/T 13554-2020 (China): Based on international standards, high-efficiency filters are classified into three grades: A, B, and C. Grade A corresponds to H13-H14 in EN 1822, requiring a filtration efficiency of ≥9% for particles 0.3μm.

- ASHRAE 52.2 (US): Based on MERV ratings, HEPA filters correspond to

- MERV 17-20, with a minimum efficiency of ≥97% (0.3μm).

*Table: Comparison of Key HEPA Filter Standards*

| Standard | Level | Test particle size | Lower efficiency requirement |

| EN 1822 | H13 | 0.3μm | 99.95% |

| GB/T 13554 | Level A | 0.3μm | 99.9% |

| ASHRAE 52.2 | MERV 17-20 | 0.3μm | 99.97% |

Common size specification

| Model | W(mm) | H(mm) | D(mm) | Rated air volume (m³/h) | Initial resistance (≤Pa) | Final resistance (Pa) | Filtration area (㎡) | Dust holding capacity (g) | Filtration efficiency |

| Z57-B-001 | 305 | 305 | 50 | 200 | 200 | 400-600 | 1.8 | 100 | H13~H14 |

| Z57-B-002 | 484 | 484 | 50 | 500 | 200 | 400-600 | 4.6 | 300 | H13~H14 |

| Z57-B-003 | 610 | 610 | 50 | 800 | 200 | 400-600 | 7.5 | 450 | H13~H14 |

| Z57-B-004 | 915 | 610 | 50 | 1200 | 200 | 400-600 | 11.2 | 700 | H13~H14 |

| Z57-B-005 | 1220 | 610 | 50 | 1600 | 200 | 400-600 | 14.9 | 900 | H13~H14 |

| Z57-B-006 | 305 | 305 | 69 | 260 | 200 | 400-600 | 2.5 | 150 | H13~H14 |

| Z57-B-007 | 484 | 484 | 69 | 700 | 200 | 400-600 | 6.6 | 400 | H13~H14 |

| Z57-B-008 | 610 | 610 | 69 | 1000 | 200 | 400-600 | 10.7 | 650 | H13~H14 |

| Z57-B-009 | 915 | 610 | 69 | 1600 | 200 | 400-600 | 16.0 | 950 | H13~H14 |

| Z57-B-010 | 1220 | 610 | 69 | 2100 | 200 | 400-600 | 21.3 | 1000 | H13~H14 |

| Z57-B-011 | 610 | 610 | 90 | 1500 | 200 | 400-600 | 14.9 | 900 | H13~H14 |

| Z57-B-012 | 915 | 610 | 90 | 2000 | 200 | 400-600 | 22.3 | 1200 | H13~H14 |

| Z57-B-013 | 1220 | 610 | 69 | 2800 | 200 | 400-600 | 29.8 | 1800 | H13~H14 |