Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

HEPA Filter Box Manufacturer in China

Providing safe and reliable terminal air filtration solutions for high-grade cleanrooms

Leading HEPA Filter Box Manufacturer & Cleanroom Solution Provider in China

As leading HEPA Filter Box Manufacturer in china, we specialize in providing high-efficiency terminal air supply and filtration system solutions for pharmaceutical, biotechnology, medical, electronics manufacturing, food processing, and laboratory clean environments.

Our HEPA filter boxes are more than just equipment—they are the guardians of the “final link” in clean air systems. They directly determine whether cleanrooms can consistently meet ISO 14644 or GMP Class A/B air cleanliness standards.

With over a decade of engineering manufacturing and cleanroom design expertise, we deliver high-performance, verifiable, and customizable HEPA Filter Box products and installation solutions tailored to diverse project scenarios—including ceiling installations, wall-mounted air supply, and negative pressure environments.

We don’t just manufacture filter boxes; we deliver an “audit-ready, traceable, and verifiable” terminal clean air system.

Explore Our HEPA Filter Box Product Range

We provide a complete clean air filtration system ranging from primary to ultra-high efficiency filtration. Our solutions serve multiple industries including electronics, pharmaceuticals, biotechnology, healthcare, and food processing.

High efficiency air supply outlet is an ideal terminal filtering device for1000,10000 and 100000 level air conditioning systems,and can bewidely used in clean air-conditioning system for medicine,health,electronics,chemical industry.High efficiency air supply outlet con-tains the plenum,diffuser plate and HEPA flters,and can be con-nected to the top or side of duct interface

| Type | Air flow | Size of flter | Overall size | Size of HEPA | Material |

| TOP/Side | m³/h | (W*h*d)mm | (W*h*d)mm | mm | Stainless Steel Box Stainless Steel Diffuser Painted Surface |

| BB-500T(S) | 500 | 415*415*93 | 485*485*435(270) | 200*200 | |

| BB-1000T(S) | 1000 | 570*570*93 | 640*600*435(270) | 320*200 | |

| BB-1500T(S) | 1500 | 570*870*93 | 640*900*435(270) | 320*250 | |

| BB-2000T(S) | 2000 | 570*1170*93 | 640*1200*435(270) | 500*250 | |

| BB-2000T(S) | 2000 | 610*915*93 | 680*965*435(270) | 500*250 |

The high efficiency exhaust outlet is applied to the high efficiency filtersystem of high-grade biosafety laboratory,which meets the require-ments of GB19489-2008“sterilizing and sterilizing the exhaust airlter in situ”in “General Requirements for Laboratory Biosafety”.

The efficient exhaust outlet is an exhaust flter device installed in theclean room,which is used for the exhaust flter of the negative pres-sure workshop system to isolate toxic,carcinogenic,radioactive andbiological dangerous dust and gas,and prevent the indoor harmfulsubstances from being discharged into the exhaust system.The deviceuses the automatic scanning and pick-up technology.The high eff-ciency air flter and the equipment frame are scanned in situ,and theflter is disinfected and sterilized through the HEPA flter by using gasdisinfectant,which can display the resistance of the high efficiency airoverizer in real tme.

| High efficiency particulate air flter | Air volume(0.9 m/s) | Box size | The wind flange | |

| circular | rectangle | |||

| HxWxD | CHM | HxWxD | φD | AxB |

| 305X305X93 | 300 | 735X465X450(+60) | 150 | 200X150 |

| 610X305X93 | 600 | 735X770×450(+60) | 200 | 200X200 |

| 610X530X93 | 1000 | 1040X690X450(+60) | 250 | 320X200 |

| 610X610X93 | 1250 | 1040X770X450(+60) | 300 | 320X250 |

| 610X762X93 | 1500 | 1040x922X450(+60) | 300 | 320X320 |

| 610X762X117 | 2000 | 1040X922X470(+60) | 350 | 400X320 |

What is a HEPA Filter Box and Why It Matters?

HEPA Filter Box (High-Efficiency Air Supply Box) serves as the terminal air filtration device in cleanroom systems, filtering air supplied into clean zones to remove particles ≥0.3μm and microbial contaminants.

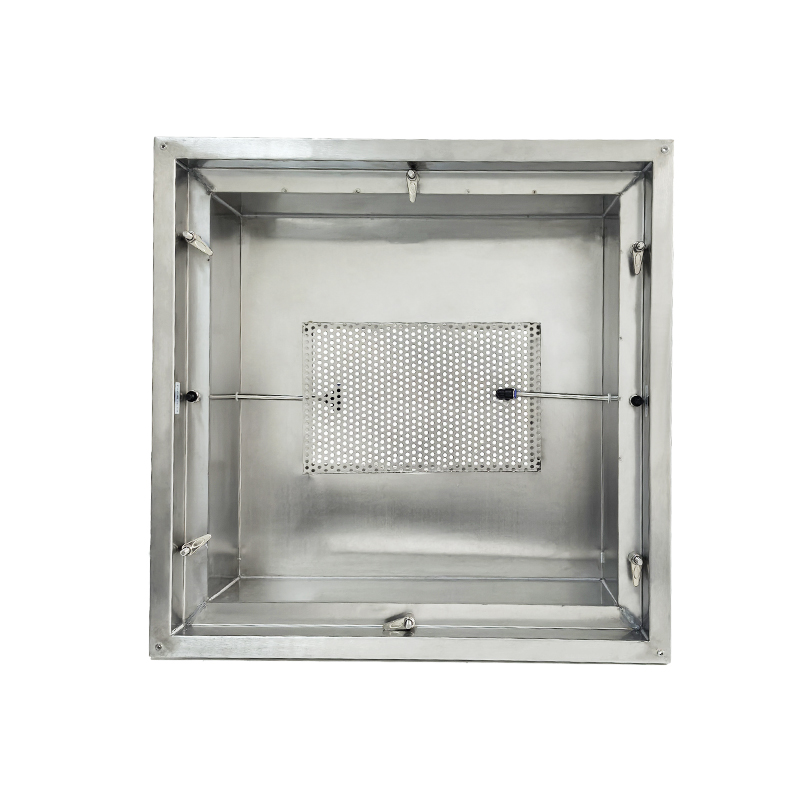

Its core structure includes:

- Enclosure (Carbon Steel / Stainless Steel / Aluminum)

- High-Efficiency Filter (HEPA or ULPA)

- Diffuser Plate

- Sealing gasket / Gel seal

- Adjustable damper and inspection port

HEPA filter boxes are typically installed at the end of cleanroom ceilings or supply ducts to achieve secondary air filtration and uniform diffusion. This ensures stable compliance with ISO standards for air velocity, direction, and cleanliness within the clean zone.

In GMP pharmaceutical and electronics manufacturing environments,

it serves as critical equipment for achieving terminal cleanliness control and preventing cross-contamination.

Key Advantages of Our HEPA Filter Box

- High-Efficiency Filtration Performance (Efficiency Up to 99.9995%@0.3μm): Utilizes internationally certified HEPA/ULPA filter cartridges, validated through EN1822 or ISO 29463 testing.

- Leak-Free Design: Utilizes gel seal or knife edge sealing methods to eliminate bypass leakage risks.

- Uniform Air Distribution: Incorporates an internal diffuser plate design to ensure consistent air velocity across the discharge surface, meeting laminar flow requirements.

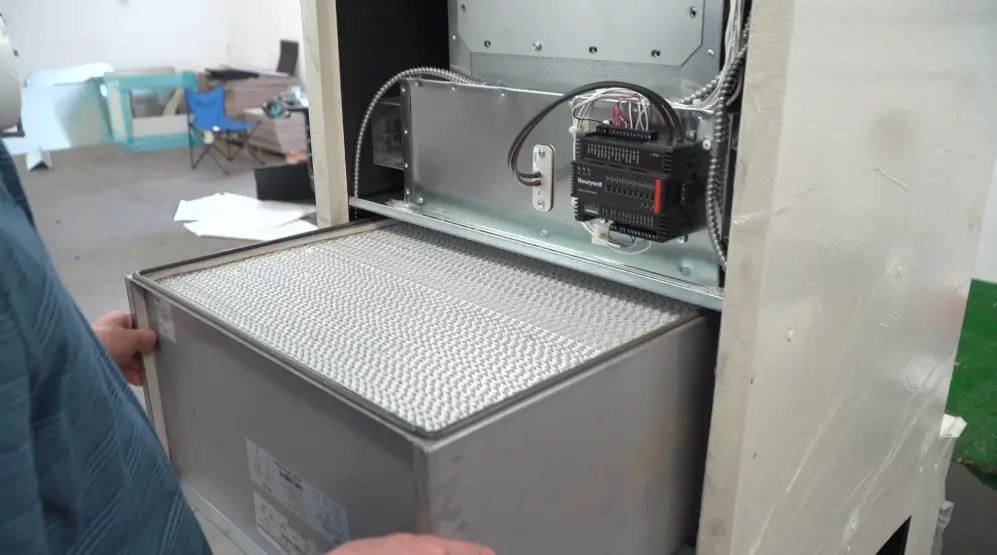

- Flexible Installation: Supports ceiling-recessed, flange-mounted, side-mounted, and other configurations to adapt to diverse cleanroom layouts.

- Easy Maintenance & Validation: Equipped with PAO (DOP) test ports and differential pressure monitoring ports for rapid on-site validation.

- Customizable & Documented: Provides complete IQ/OQ/PQ validation documentation, material certificates, and test reports to meet GMP/FDA audit requirements.

Cleanroom Applications of Our HEPA Filter Box

Our filters have been widely adopted in numerous cleanroom systems. You can obtain professional cleanroom filter solutions directly from the HEPA aire filter manufacturer.

Cleanroom terminal air supply and air recirculation systems

Negative pressure containment and high-efficiency terminal filtration

Laminar airflow supply and air isolation systems

Clean production line terminal air filtration

Filling and packaging clean space control

Expand Your Business with Our HEPA Air Filter Box Manufacturing Capabilities

In this era of rapid advancements in clean air technology, choosing the right partner means gaining a competitive edge in project delivery speed, product quality, and system compliance.

We operate an advanced HEPA filter box production line, fully automated metalworking equipment, and dust-free assembly workshops, supported by a quality management system certified to ISO 9001 and EN 1822 standards.

Each HEPA Filter Box undergoes rigorous airtightness testing, PAO/DEHS leakage detection, and airflow uniformity validation, ensuring stable operation in any global cleanroom system while meeting ISO 14644, GMP, FDA, and other international standards.

Leveraging our extensive OEM/ODM manufacturing experience and engineering support capabilities, you gain not only high-performance HEPA filter box products but also expand your market supply capacity and enhance brand competitiveness through our production advantages: high consistency, short lead times, customizability, and verifiability.

Partnering with us means gaining not just products, but a professional manufacturing team that understands air systems,

recognizes customer needs, and prioritizes long-term collaboration. Let our exceptional HEPA filter box manufacturing capabilities provide powerful momentum for your global business expansion.

Frequently Asked Questions about HEPA Filter Box Manufacturer

What is the difference between a HEPA Filter Box and a HEPA Filter?

Answer:

A HEPA Filter is a standalone filtration element, while a HEPA Filter Box is a complete terminal filtration system, typically comprising a filter, housing, airflow distribution plate, sealing gasket, inspection port, and damper.

The filter box provides an installation sealing structure and uniform airflow distribution, ensuring more stable and reliable air cleanliness.

What is the filtration efficiency of the HEPA Filter Box?

Answer:

Our HEPA Filter Box utilizes H13–U15 grade filter cartridges (EN1822 / ISO 29463 standard), achieving filtration efficiency of 99.995%–99.999% (99.99995%@0.3μm). It is suitable for various high-grade cleanrooms, operating rooms, biological laboratories, and microelectronics manufacturing environments.

Do you offer customized services?

Answer:

Yes. We provide comprehensive OEM/ODM customization services, including personalized designs for enclosure materials (galvanized steel/stainless steel/aluminum alloy), sealing methods (gel seal/gasket/knife edge), airflow volume, structural dimensions, and interface orientation. We also offer one-to-one engineering customization based on clients’ cleanroom system drawings.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.