Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

Pre-Air Filters for Cleanroom Systems

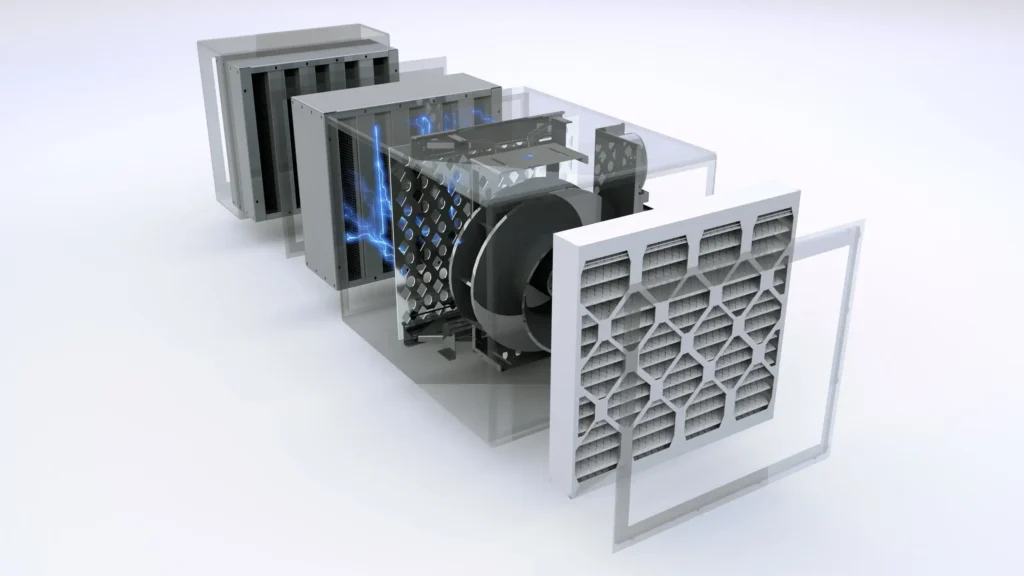

The First Line of Defense for High-Efficiency Cleanroom Air Systems

Leading Pre-Air Filter Manufacturer & Supplier in China

As China’s leading manufacturer and supplier of Pre-Air Filters, we specialize in providing high-performance, energy-efficient, and validated air pre-filtration solutions for cleanroom systems, HVAC systems, pharmaceutical plants, biological laboratories, and the electronics manufacturing industry.

With over a decade of clean air system manufacturing and project experience, we deeply understand the hierarchical logic of cleanroom air filtration:

Pre-Filters serve as the “gatekeepers” of the entire clean air system—they determine system stability, energy consumption levels, and the lifespan of high-efficiency filters.

Our primary filter product line encompasses flat panel, bag, pleated, metal mesh, and washable designs. All products comply with international standards including ISO 16890, EN779, ASHRAE 52.2, GMP, and FDA, enabling broad application across diverse clean systems and air handling equipment.

We deliver not just filters, but comprehensive front-end protection solutions for clean air systems.

Explore Our Pre-Air Filter Product

We provide a complete clean air filtration system ranging from primary to ultra-high efficiency filtration. Our solutions serve multiple industries including electronics, pharmaceuticals, biotechnology, healthcare, and food processing.

| Model number | Overall dimension LxW×D | Rated air volume(m3/h) | Initial resistance(Pa) | |

| Weighing effciency(G4) 90%≤A | Counting efficiency (M5@0.4nm)40%≤E<60% | |||

| BB592.592-46 | 592×592×46 | 3400 | 40 | 60 |

| BB287.592-46 | 287×592×46 | 1700 | ||

| BB492.492-46 | 492×492×46 | 2200 | ||

What is a Pre-Air Filter?

The Pre-Air Filter is the foremost filtration component in clean air systems. It primarily removes larger airborne particles such as dust, pollen, fibers, and suspended particles to prevent these contaminants from entering the medium-efficiency or high-efficiency filtration stages, where they could cause clogging or efficiency degradation.

It is typically installed at:

- The air intake of air handling units (AHU/HVAC);

- The pre-filter section of cleanroom supply air systems;

- The front-end protection position for high-efficiency filters (HEPA/ULPA).

The core value of the Pre-Filter lies not only in its filtration function but also in its ability to significantly reduce maintenance costs and energy consumption for downstream systems. It ensures the overall stability and economical operation of cleanroom systems.

Key Performance Advantages of Pre-Air Filters

- High Dust Holding Capacity: Features a progressively denser filter media structure to maintain stable airflow and low pressure drop over extended periods.

- Protect HEPA & HVAC System: Effectively extends the lifespan of high-efficiency filters while reducing maintenance and replacement frequency.

- Low Resistance & Energy Saving: Optimized pleated structure design maintains high airflow while minimizing energy consumption.

- Global Compliance: All products certified and tested to ISO 16890, EN779, and ASHRAE 52.2 standards.

- Reusable Options: Select models support multiple wash cycles for reuse, reducing operational costs and carbon footprint.

- Customizable Solutions: Tailored dimensions, media, frame materials, and filtration grades to meet diverse cleanroom requirements.

Cleanroom Applications of Our HEPA Filters

Our filters have been widely adopted in numerous cleanroom systems. You can obtain professional cleanroom filter solutions directly from the HEPA aire filter manufacturer.

Prevent microbial contamination, comply with GMP and FDA requirements

Controls nanoscale particles to meet ISO Class 5–6 cleanliness standards

Ensures sterile air to prevent cross-contamination

Reduces airborne contaminants to extend product shelf life

Stabilizes airflow patterns to guarantee experimental data reliability

Frequently Asked Questions about Pre-Air Filters

What is the filtration efficiency of Pre-Air Filters?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

What materials are used to manufacture Pre-Air Filters?

Answer:

We offer multiple material options, including:

- Synthetic Fiber – Cost-effective and versatile;

- Glass Fiber – Excellent stability and high filtration efficiency;

- Aluminum / Stainless Steel Mesh – Reusable and suitable for industrial environments.

How long is the service life of a primary filter?

Answer:

Under normal air quality conditions, the typical lifespan is 3–6 months. For washable models, they can be cleaned and reused for up to 5–10 cycles. Replacement is recommended based on differential pressure monitoring results or airflow decay.

Can Pre-Air Filters be washed or reused?

Answer:

Yes, certain models (such as metal mesh or synthetic fiber types) can be washed with water or blown clean. When cleaning, use a gentle water stream and a neutral detergent. Reinstall only after the filter is completely dry to maintain its filtration performance.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.