Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

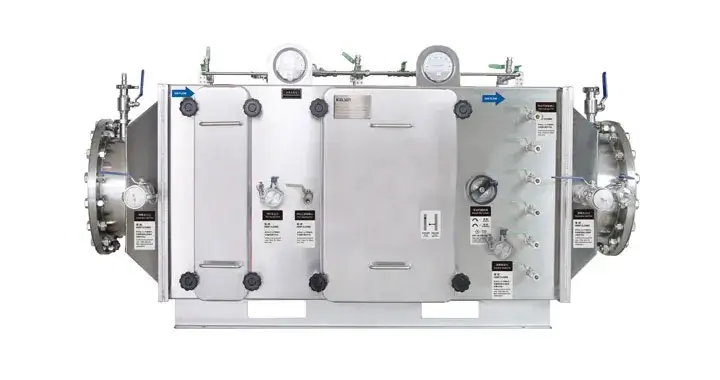

Bag in Bag Out Filter Systems

High-Security Clean Air Filtration Bag in Bag Out System Manufacturer, Safeguarding Every Breath in Clean Spaces

Leading Bag In Bag Out Filter System Manufacturer in China

As China’s leading manufacturer of Bag-in-Bag-out (BIBO) Filter Systems, we specialize in providing safe, verifiable filtration solutions for global high-cleanliness and high-protection industries. With over a decade of experience in cleanroom air system manufacturing, we have accumulated extensive expertise in design, production, and validation. This enables us to meet the stringent air isolation requirements of applications such as pharmaceuticals, nuclear medicine, and pathogen laboratories (BSL-2 to BSL-4).

Our BIBO systems strictly adhere to international standards including ISO 14644, EN1822, ASHRAE, GMP, FDA, WHO, and NIH, achieving an optimal balance of filtration performance, safe replacement, contamination control, and maintenance convenience. Each unit undergoes airtightness testing, HEPA leakage detection, and operational safety assessment prior to shipment, ensuring reliable operation in extreme cleanroom and hazardous environments.

Explore Our Bag in Bag Out Filter System

Brief Description:

The Bag-in/Bag-out filter, also known as the Bag-in/Bag-out filtration unit, is commonly referred to as BIBO or the duct-mounted high-efficiency exhaust filtration device.

Since the filter intercepts highly reactive or toxic hazardous aerosols during operation, replacement must ensure zero contact between the filter cartridge and the external environment. Therefore, a sealed bag replacement method is employed, hence the name Bag-in/Bag-out filter. Its use effectively prevents the spread of harmful aerosols, avoiding biological hazards to personnel and the environment. This filtration system is specifically designed for environments with defined biological risks, capable of removing harmful biological aerosols from exhaust air. It typically incorporates both in-situ sterilization and leak detection capabilities.

Standard Size And Basic Performance Parameters

| Model number | Overall dimension WxDxH | Filter size WxDxH | Rated air volume (m3/s) |

| BB-LWB1700 | 400x725x900 | 305x610x292 | 1700 |

| BB-LWB3400 | 705x725x900 | 610x610x292 | 3400 |

| BB-LWB5100 | 705x1175x900 | * | 5100 |

What Is a Bag in Bag Out Filter System?

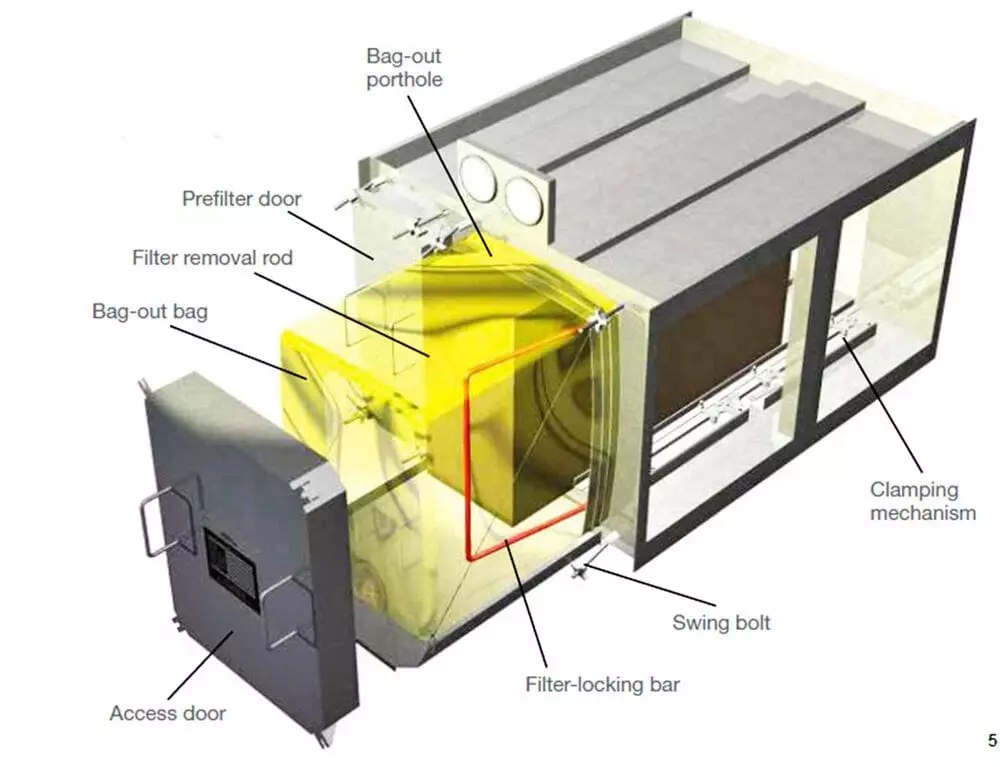

The Bag-In Bag-Out Filter System (BIBO system) is a filtration device designed for high-security cleanrooms. Its “bag-in/bag-out” design ensures zero contamination exposure during filter element replacement.

The core principle of the system is:

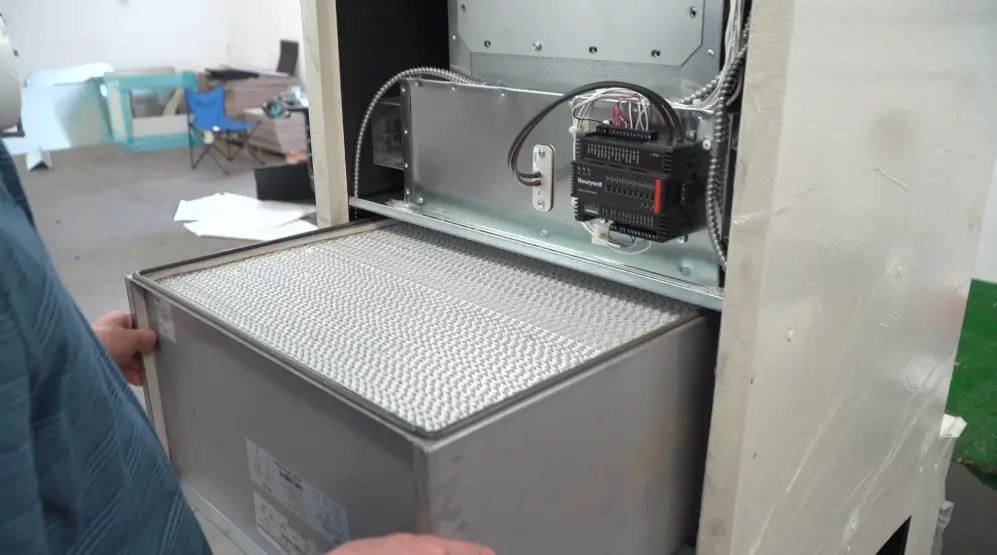

During installation and replacement of filter elements (typically HEPA or ULPA), the filter, sealing rings, and housing are completely isolated from the external environment. Operators perform filter element removal and installation through a sealed operating bag, eliminating direct contact with potential contaminants.

It is widely used in:

- Toxic or radioactive particle filtration systems

- Pathogen laboratories (BSL-3/BSL-4)

- High-risk raw material processing areas in pharmaceutical plants

- Nuclear facilities and biological containment ventilation systems

In short:

The Bag-in Bag-out Filter System serves as a critical “defense barrier” for personnel and environmental safety in clean filtration.

It enables efficient filtration and secure maintenance without compromising airtight integrity.

Applications of Cleanroom Bag in Bag Out Filter System

Bag-in Bag-out Filter Systems are widely used in the following high-protection cleanroom environments.

Why Should You Use a Bag In Bag Out Filter System?

- Protecting Operator Safety: The fully sealed “bag-in-bag-out” design prevents operators from contacting contaminants during filter replacement, eliminating exposure risks.

- Preventing Contaminant Leakage: The system features a highly airtight enclosure with dual-seal construction, ensuring no contaminants escape during filter changes.

- Reducing Maintenance Risks and Costs: The safe, rapid replacement process requires no system disassembly or downtime, significantly lowering maintenance complexity and duration.

- Safeguarding Environmental and Personnel Health: Effectively prevents contaminant spread, protects cleanroom environments and worker safety, and ensures production process compliance.

✅ The BIBO system is an indispensable safety filtration solution for high-risk clean areas.

Bag In Bag Out (BIBO) Filter System Technical Data

| Parameter Category | Specification | Standard / Reference |

|---|---|---|

| Filter Type | HEPA (H13/H14) or ULPA (U15/U16) | EN1822 / IEST RP-CC001 |

| Filtration Efficiency | ≥ 99.995% @ 0.3 μm (H14) | ISO 14644 / EN1822 |

| Housing Material | SUS304 / SUS316L / Carbon Steel with Epoxy Coating | GMP / FDA / ISO 14644 |

| Seal Type | Gel Seal / Knife-edge Gasket Seal | EN1822 / NIH Guidelines |

| Leakage Class | ≤ 0.5 Pa (Class 3 Airtightness) | ISO 10648-2 |

| Replacement Method | Bag-In Bag-Out (Fully Enclosed Safe Change) | NIH / WHO / ISO 14644 |

| Pressure Differential Range | 0 – 500 Pa (Adjustable with Differential Pressure Gauge) | EN ISO 21501 |

| Prefilter Efficiency | ≥ 85% @ 5 μm | EN779 / ISO 16890 |

| HEPA Filter Frame | Aluminum Alloy / Stainless Steel | EN1822 |

| Installation Orientation | Horizontal / Vertical / Modular Configurations | Project-specific |

| Surface Finish | Polished Surface, Ra ≤ 0.8 μm | GMP Design Requirement |

| Monitoring System (Optional) | Pressure Sensor, HEPA Leakage Alarm, Air Velocity Display | Client Request |

| Decontamination Compatibility | Compatible with H₂O₂, IPA, and UV Sterilization | Internal Standard |

| Airflow Capacity | Customizable (Typical: 500 – 5000 m³/h per module) | Engineering Design |

| Operating Temperature | ≤ 70°C Continuous Operation | Internal Standard |

| Certification | ISO 9001 / CE / SGS / CNAS | International Compliance |

The Bag-in Bag-out Filter System serves as one of the most critical air safety barriers in clean environments. It not only ensures air cleanliness but also protects personnel, experimental settings, and external environments from contamination risks.

As China’s leading manufacturer of clean air systems, we deliver safe, traceable, and verifiable BIBO filtration solutions to global customers through scientific design, rigorous manufacturing, and international standard validation.

Why Custom BIBO from China Manufacturer?

Choosing a Chinese manufacturer to customize your BIBO system is not only about achieving a better cost-performance ratio, but also about gaining access to professional technical support, sustainable supply, and globally compliant quality assurance.

Why Choose Chinese Manufacturers for Custom Bag-in-Bag-out (BIBO) Filtration Systems?

In high-protection cleanrooms, every Bag-in-Bag-out (BIBO) filtration system must be customized according to the site environment, ventilation methods, airflow direction, and maintenance procedures. Selecting an experienced Chinese BIBO system manufacturer achieves the optimal balance between technical expertise, manufacturing costs, and delivery timelines.

After over a decade of development, China’s cleanroom manufacturing industry has established a complete industrial chain and rigorous quality systems. This encompasses stainless steel structural fabrication, HEPA filter module production, airtightness testing, and intelligent control system integration.

Compared to imported equipment, Chinese manufacturers deliver faster lead times, more competitive costs, and equivalent technical standards. They provide safe, reliable, and verifiable filtration solutions for pharmaceutical, biosafety laboratory, nuclear medicine, and chemical protection projects.

Whether it involves horizontal or vertical configurations, single- or double-layer filter modules, HEPA/ULPA configurations, airtight structures, or intelligent monitoring and remote alarm systems, Chinese manufacturers can precisely customize solutions to meet client requirements while providing comprehensive validation documentation to support project audits.

Frequently Asked Questions about Bag In Bag Out Filter Systems

Why is the BIBO system safer than conventional HEPA boxes?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

How often should the BIBO filter be replaced?

Answer:

It is generally recommended to inspect the pressure differential and filtration efficiency every 6–12 months.

The HEPA filter element should be replaced when the pressure differential exceeds the set threshold (typically ≥250 Pa) or when airflow decreases significantly. We can provide customers with filtration lifespan assessments and maintenance plans tailored to different operating conditions.

Can the BIBO system be compatible with existing HVAC or exhaust systems?

Answer: Absolutely.

The BIBO system features a modular structure that supports horizontal or vertical installation and integrates seamlessly with existing clean ventilation ducts, fume hoods, or negative pressure systems. We provide customized designs based on project airflow volume and pressure differentials.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.