Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

Cleanroom Air Filter Solutions

Clean Air System Solutions Specialist, Crafting Precision Filtration for Every Clean Space

Leading Cleanroom Air Filter Solutions Provider in China

As leading Cleanroom Air Filter Solutions supplier in china, we specialize in delivering comprehensive air filtration system solutions for global cleanroom projects, pharmaceutical plants, biological laboratories, electronics manufacturing, and healthcare industries.

We understand that stable air cleanliness depends not only on individual filter performance but also on the rational design and consistent maintenance of the entire system. Therefore, our solutions comprehensively cover the entire process: primary filtration → medium filtration → high-efficiency HEPA/ULPA filtration → system validation. This ensures cleanrooms consistently meet ISO 14644 or GMP Class A/B requirements under any operating conditions.

We deliver not just products, but a scientifically validated air purification system that empowers clients to achieve “safe, energy-efficient, and stable” cleanroom operations.

Explore Our Cleanroom Air Filter Product Line

We provide a complete clean air filtration system ranging from primary to ultra-high efficiency filtration. Our solutions serve multiple industries including electronics, pharmaceuticals, biotechnology, healthcare, and food processing.

What Is a Cleanroom Air Filter Solution?

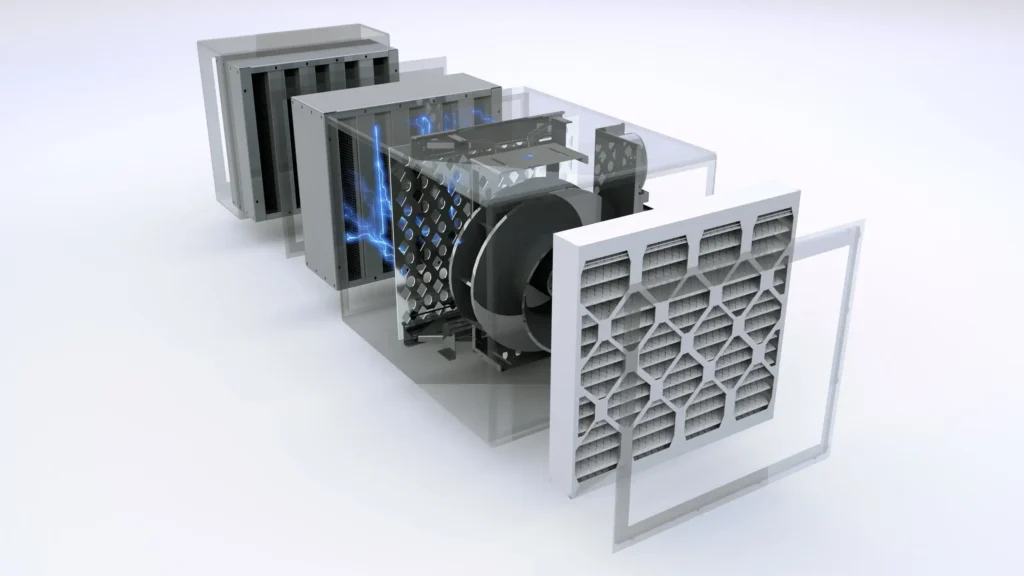

Cleanroom Air Filter Solutions provide a systematic approach to air purification. By combining different filter types with airflow control systems, they effectively manage particulate matter, microorganisms, and airborne contaminants within cleanrooms, laboratories, or industrial production areas.

A complete system typically includes the following tiers:

- Pre-filter: Intercepts larger dust particles and fibers, extending the lifespan of downstream filters;

- Medium Filter: Filters medium-sized particles and stabilizes system negative pressure;

- HEPA/ULPA Filter: Removes particles ≥0.3μm to achieve cleanroom-grade air quality;

- Terminal Frame / Fan Filter Unit: Delivers and uniformly distributes clean air;

- Monitoring & Validation System: Ensures air velocity, differential pressure, and filtration efficiency meet standards.

This system serves as the “central hub” for cleanroom air purification. No high-grade clean space (GMP / ISO / FDA) can function without an efficient filtration solution.

Key Advantages of Our Air Filter Solutions

- Multi-stage filtration structure ensures clean air stability: A multi-layer filtration combination from primary to high-efficiency filters guarantees continuous clean air supply, achieving filtration efficiency up to 99.995%@0.3μm (H14 grade).

- Internationally validated system: All filters pass EN1822 / ISO 29463 / IEST RP-CC001 testing, with comprehensive inspection and validation reports provided.

- Flexible modular design: Customizable airflow, dimensions, and installation methods to suit diverse cleanroom layouts. Supports ceiling-recessed, side-supply, or fan-integrated configurations.

- Energy-efficient and low-resistance design: Utilizes low-resistance filter media and optimized ductwork to reduce system energy consumption and extend filter cartridge lifespan.

- Full lifecycle support: We provide not only filters but also installation, commissioning, air velocity testing, and periodic maintenance services.

Typical Applications of Our Air Filter Solutions

Cleanroom Air Filter Solutions are widely used across all industries with stringent requirements for air purity, safety, and stability. They serve as critical systems for achieving high-quality production and environmental control.

Used in drug production, weighing, filling, and packaging areas to ensure air cleanliness meets GMP Class A/B standards and prevent product contamination.

Maintains controlled microbial and particulate contamination during cell culture, vaccine development, and testing experiments.

Used in operating rooms, ICUs, sterile wards, and similar areas to provide continuous high-cleanliness air assurance.

Delivers ultra-clean air for chip, display, and optical component production to prevent particle-induced defects.

Prevents particle and odor contamination during filling, mixing, and testing processes to ensure consistent product quality.

Why Choose Us as Your Cleanroom Air Filter Solutions Partner

In the field of clean air control, reliable production capacity translates to heightened market competitiveness. As China’s leading HEPA air filter manufacturer, we not only supply high-efficiency air filtration products to global customers but also empower partners to achieve business growth and brand elevation through our robust manufacturing systems and engineering expertise.

We don’t just manufacture filters—we help clients build scientific, efficient, and traceable air purification systems.

- Over 15 years of clean air system manufacturing and validation experience

- Products certified to ISO 9001, CE, EN1822, and SGS standards

- Complete GMP validation documentation (IQ/OQ/PQ) and test reports

- Supports OEM/ODM customization: Structure, efficiency, dimensions, and sealing methods can all be tailored

- Technical team provides air system assessment, validation, and energy optimization recommendations

- Global service network for rapid delivery and after-sales support

Frequently Asked Questions about Cleanroom Air Filter Solutions

What is the difference between HEPA and ULPA?

Answer:

HEPA (High Efficiency Particulate Air) filters remove particles ≥0.3μm with an efficiency of ≥99.97%.

ULPA (Ultra Low Penetration Air) filters remove particles ≥0.12μm with an efficiency as high as ≥99.9995%.

ULPA is suitable for industries with extremely high cleanliness requirements, such as semiconductors and optics.

How often should filters be replaced?

Answer:

Typical recommendations are:

- Primary filters: Replace every 3–6 months;

- Medium-efficiency filters: Replace every 6–12 months;

- HEPA/ULPA filters: Replace every 12–18 months or based on differential pressure readings.

We recommend periodic evaluation using differential pressure gauges or monitoring system data.

How to Select the Right Air Filtration System?

Answer:

Selecting a filtration system should be based on:

- Cleanroom Class (ISO Class)

- Application Scenario (Pharmaceutical, Electronics, Laboratories, etc.)

- Airflow Volume and Differential Pressure Requirements

- Need for Energy-Efficient or Serviceable Design

Our engineering team can provide professional air system evaluations and configuration recommendations.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.