Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

China Cleanroom Windows Manufacturer in China

Professional Cleanroom Window System Manufacturer and Integrated Solutions Provider

About Us — Leading Cleanroom Windows Manufacturer in China

As leading cleanroom window system manufacturer in China, we specialize in providing high-performance, verifiable clean window solutions for the global cleanroom industry. With over a decade of professional manufacturing and engineering expertise, we have served pharmaceutical, biotechnology, electronics, medical, and food industries worldwide. Our products are exported to over 30 countries and regions, earning a strong reputation and trust in the international market.

Our philosophy is straightforward:

A cleanroom window is not merely a visual aperture—it is a critical protective component within the clean space system.

Therefore, we adhere to the principles of “scientific design, precision manufacturing, and rigorous validation” throughout product development and production. This ensures every window meets the highest standards for airtightness, anti-static properties, optical performance, and structural stability.

We hold ISO 9001 quality system certification and have passed third-party testing certifications including CE, SGS, and CNAS.

All Cleanroom Windows comply with international standards such as ISO 14644, EN14509, GB50073, GMP, and FDA.

Our advantage extends beyond products to systematic services:

We provide end-to-end technical support—from design solutions → custom manufacturing → installation guidance → validation support—tailored to clients’ cleanroom wall systems, structural layouts, and project environments.

Our Cleanroom Windows Product Series

As a professional China Cleanroom Windows Manufacturer, we offer cleanroom window systems in various structural configurations and functional specifications. All products feature high-strength tempered glass paired with aluminum alloy or stainless steel sealed frames.

| Parameter Category | Standard Value | Test Standard / Method |

|---|---|---|

| Air Tightness | ≤ 0.5 Pa pressure leakage | ISO 14644 / GB50073 |

| Light Transmittance | ≥ 88% | ASTM E308 |

| Surface Resistance | ≤ 10⁹ Ω | IEC 61340 |

| Fire Resistance Rating | Class A1 / B1 | EN13501-1 |

| Antibacterial Performance | ≥ 99% antibacterial rate | ISO 22196 |

| Anti-fog Performance | No condensation for >1000 hours | Internal Quality Test Standard |

What Are Cleanroom Windows?

Cleanroom Windows are sealed components within cleanroom wall systems designed for visual observation and daylighting. They serve not only as “windows” for personnel to monitor activities within the clean zone but also as critical structural elements in maintaining the cleanroom system’s airtightness, contamination prevention, and stable airflow patterns.

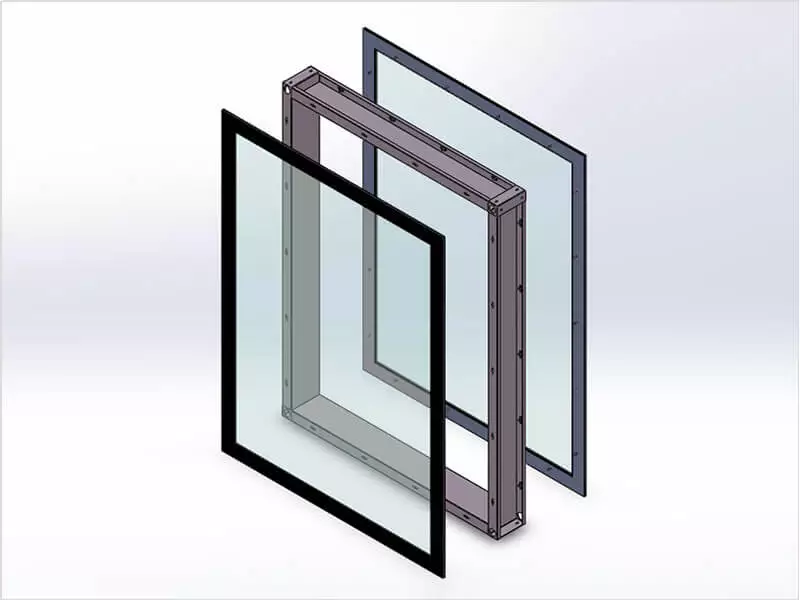

Unlike conventional building windows, Cleanroom Windows feature a fully sealed, dust-free assembly structure. Typically composed of double-pane tempered glass within an aluminum alloy or stainless steel frame, they incorporate anti-static, anti-fog, and antimicrobial coatings. This ensures long-term operation without generating particulate contamination in high-cleanliness environments (ISO Class 5–8).

A high-quality cleanroom window is not merely a transparent component that is “visible”; it is a critical safeguard for air control, safety, and compliance within cleanrooms. It allows light to enter the clean space without permitting any contamination to follow.

Advantages of Cleanroom Windows

- Excellent Air Tightness: Features a fully sealed structure with high-precision sealing gaskets to prevent air leakage and particle ingress, maintaining stable pressure differentials within clean zones.

- Anti-fog & Condensation-free Design: Hollow structure filled with inert gas and equipped with desiccant ensures clear visibility without condensation, even during prolonged operation.

- Anti-static Performance: Glass surfaces feature anti-static coating to prevent dust adhesion and electrostatic interference, making it suitable for electronics and semiconductor cleanrooms.

- Superior Optical Clarity: Utilizes high-transmittance tempered glass with a flat, distortion-free surface, ensuring natural daylighting and visual comfort.

- Structural Stability & Safety: Combines high-strength tempered glass with an aluminum alloy frame for impact resistance and corrosion protection, guaranteeing long-term stable use.

- Easy Cleaning & Aesthetic Design: Flush-mounted installation eliminates dust-trapping corners, facilitating effortless cleaning while maintaining an elegant appearance that meets GMP design requirements.

- Customization & Compatibility: Supports customization in dimensions, thickness, glass types, and anti-fog heating options. Seamlessly integrates with various clean wall systems.

Cleanroom Applications of Our Cleanroom Windows

Cleanroom Windows are widely used in any environment requiring air cleanliness control and visual management. They not only enhance the brightness and safety of the space but also serve as critical components in maintaining airtightness, dust prevention, and hygiene compliance within cleanroom systems.

Sterile production lines, filling areas, QC laboratories

Lithography areas, testing rooms, assembly zones

Operating rooms, ICUs, isolation wards

Clean packaging workshops

Biological laboratories (BSL2/BSL3), testing centers

Why Choose Us as Your Cleanroom Windows Manufacturer in China?

Choosing us as your Cleanroom Windows Manufacturer in China means selecting a trusted, technologically advanced, and quality-verified long-term partner. We not only manufacture cleanroom windows but also provide customers with complete visualization solutions for clean spaces.

With over 15 years of cleanroom system manufacturing experience, we deeply understand the critical role of cleanroom windows in airtightness, dust prevention, anti-static properties, and visual management.

Furthermore, all products are strictly manufactured in compliance with ISO 14644, GMP, FDA, and CE standards. They undergo rigorous testing for airtightness, anti-fogging, anti-static properties, and optical performance to ensure long-term stable operation.

Our factory is equipped with automated insulated glass assembly lines and precision CNC machining equipment, supporting OEM/ODM customization services to flexibly meet diverse project requirements for dimensions, structures, and functionalities. We provide rapid delivery, technical guidance, and comprehensive after-sales support to customers in over 30 countries worldwide.

Choosing us means choosing consistent quality, professional support, and a sustainable partnership.

Frequently Asked Questions about Cleanroom Windows

Will the clean window fog up or develop condensation?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

Will the clean window fog up or develop condensation?

Answer: All cleanroom windows undergo airtightness testing, with a pressure differential leakage rate controlled at ≤0.5Pa. They fully comply with ISO 14644 and GB50073 cleanroom standards, ensuring long-term stability of pressure differentials within clean zones and preventing leakage of particles and contaminated gases.

Can production be customized?

Answer: Yes.

We support OEM/ODM customization and can tailor products based on customer drawings or project requirements, including: dimensions, thickness, frame material, glass type, color, anti-static or anti-fog functionality, etc.

Whether it’s standard cleanroom wall systems or non-standard engineering structures, we can match production accordingly.

How are cleanroom windows installed?

Answer:

Our cleanroom windows feature a modular design that allows flush-mounted installation with cleanroom wall systems (such as color-coated steel panels, stainless steel panels, aluminum honeycomb panels, etc.).

We provide comprehensive installation instructions, technical drawings, and video guides. The construction process is straightforward, dust-free, and can be completed quickly.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.