Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

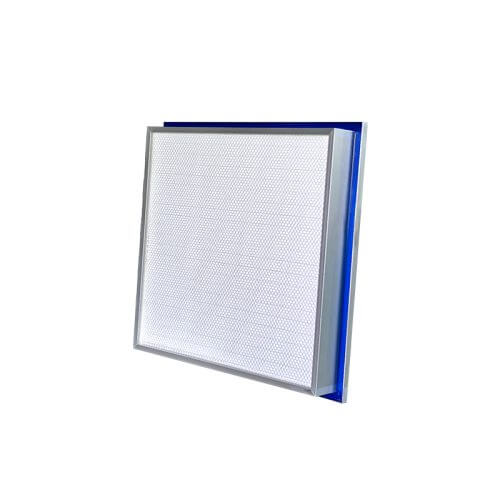

Cleanroom High-Efficiency Air Filters

Providing stable, compliant, and reliable high-efficiency air filtration solutions for cleanroom systems

Leading Cleanroom High-Efficiency Air Filter Manufacturer in China

As leading Cleanroom High-Efficiency Air Filters manufacturer and solutions provider in china, we specialize in delivering efficient, energy-saving, and validated clean air filtration systems for the pharmaceutical, biotechnology, electronics manufacturing, healthcare, and laboratory industries.

With over a decade of experience in designing and manufacturing air purification systems, we understand the critical importance of cleanroom air quality. It not only determines product yield rates but also impacts the safety and compliance of the entire production environment.

All our high-efficiency filtration products strictly comply with international standards including ISO 14644, EN1822, IEST RP-CC001, GMP Annex 1, and FDA regulations. They undergo multiple performance validations, including efficiency testing, air leakage testing, MPPS testing (Most Penetrating Particle Size), and airtightness inspection.

We don’t just manufacture filters; we are committed to building a comprehensive system defense line from air to product safety.

Explore Our High-Efficiency Air Filter Product Line

We provide a complete clean air filtration system ranging from primary to ultra-high efficiency filtration. Our solutions serve multiple industries including electronics, pharmaceuticals, biotechnology, healthcare, and food processing.

| MODEL | L×W×D | (m³/h) | Initial Pressure Drop(Pa) | Final Pressure Drop(Pa) | @MPPS |

| BB410.410-93H14 | 410x410x93 | 500 | 220 | 450 | 99.995%≤E<99.9995% |

| BB550.550-93H14 | 550x550x93 | 1000 | |||

| BB650.650-93H14 | 650x650x93 | 1500 | |||

| BB750.750-93H14 | 750x750x93 | 2000 | |||

| BB370.370-93H14D | 370×370×104 | 500 | |||

| BB510.510-93H14D | 510x510x104 | 1000 | |||

| BB610.610-93H14D | 610×610×104 | 1500 | |||

| BB710.710-93H14D | 710x710x104 | 2000 |

What is a Cleanroom High-Efficiency Air Filter?

Cleanroom High-Efficiency Air Filters are terminal air purification devices specifically designed for controlled environments (cleanrooms). Their core function is to remove airborne particulates, bacteria, dust, and contaminants, ensuring air cleanliness meets ISO Class 5–8 (Class 100–100,000) or higher requirements.

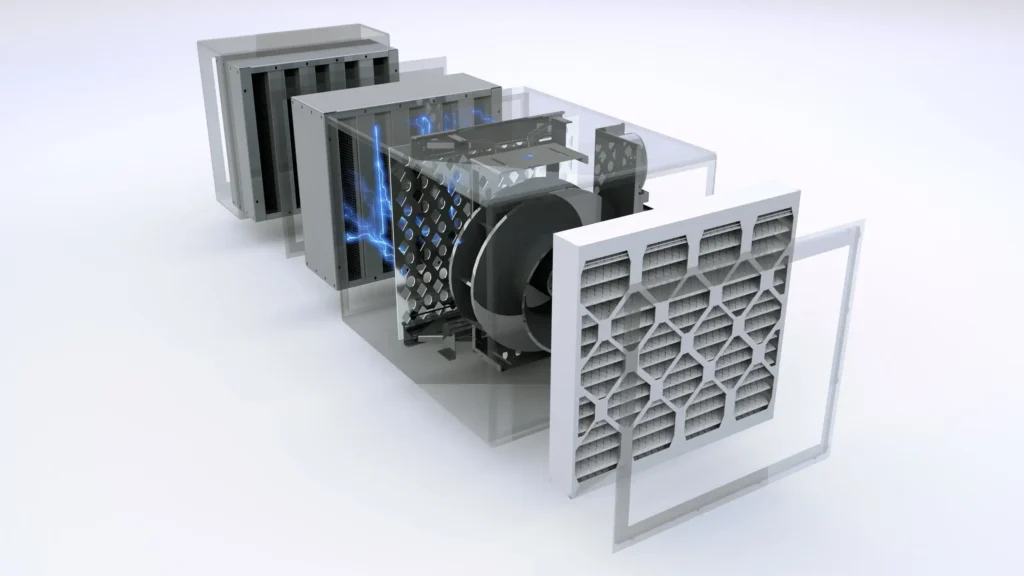

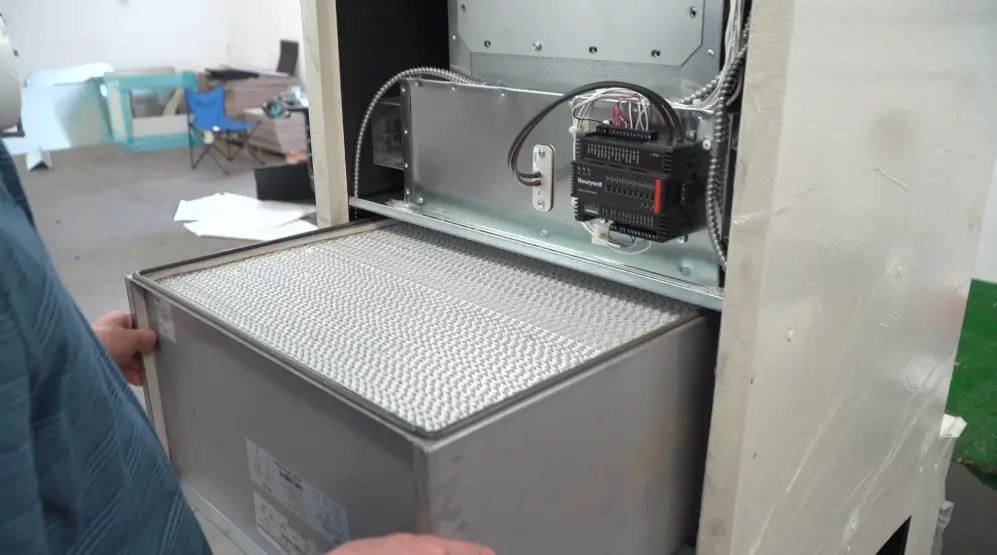

These filters are typically installed at the end of cleanroom supply air systems or within fan filter units (FFUs). Utilizing HEPA or ULPA filter media, they achieve filtration efficiencies as high as 99.97% to 99.99995%@0.3μm.

They serve as the “final line of defense” in clean air systems, directly determining whether a cleanroom can operate stably and pass validation.

Key Performance Advantages of High-Efficiency Air Filter?

- Superior Filtration Efficiency: Utilizes imported glass fiber filter paper or PTFE membrane material, achieving filtration efficiency up to 99.9995%.

- Low Resistance & High Airflow Design: Optimized pleated structure and fluid dynamics air channels reduce energy consumption and extend filter lifespan.

- Zero Leakage Design: Gel Seal or Knife Edge structures ensure no bypass leakage.

- Global Compliance: Certified and third-party tested to EN1822, ISO 29463, IEST, GMP, FDA, and other international standards.

- Flexible Installation: Compatible with FFU modules, ceiling systems, wall mounting, or BIBO systems to accommodate diverse cleanroom layouts and airflow requirements.

- Custom & Validation Ready: Offers personalized customization for dimensions, frame materials, sealing methods, airflow rates, and test reports, complete with IQ/OQ/PQ validation documentation for audit compliance.

Cleanroom Applications of Our HEPA Filters

Our filters have been widely adopted in numerous cleanroom systems. You can obtain professional cleanroom filter solutions directly from the HEPA aire filter manufacturer.

Prevent microbial contamination, comply with GMP and FDA requirements

Controls nanoscale particles to meet ISO Class 5–6 cleanliness standards

Ensures sterile air to prevent cross-contamination

Reduces airborne contaminants to extend product shelf life

Stabilizes airflow patterns to guarantee experimental data reliability

Expand Your Business with Our HEPA Air Filter Manufacturing Capabilities

In the field of clean air control, reliable production capacity translates to heightened market competitiveness. As China’s leading HEPA air filter manufacturer, we not only supply high-efficiency air filtration products to global customers but also empower partners to achieve business growth and brand elevation through our robust manufacturing systems and engineering expertise.

Our production system features fully automated lines for filter paper folding, adhesive application, assembly, and leak scanning, with an annual production capacity exceeding 300,000 high-efficiency filters. All products are manufactured in a Class 10,000 cleanroom environment and validated against authoritative standards including EN1822, IEST-RP, and ISO 9001, ensuring each filter delivers consistent filtration efficiency, low resistance, and extended service life.

We understand diverse market demands for HEPA filters. Therefore, we support:

- OEM/ODM Customization Services — Production tailored to client branding and specifications;

- Flexible Production & Low Minimum Order Quantities — Adaptable for project-based delivery and new product trials;

- Multi-Specification Compatibility — Covering the full range: Mini-pleat, Separator, Gel Seal, V-Bank, and ULPA products;

- Technical documentation and testing reports — Providing factory inspection data, MPPS efficiency curves, and airflow distribution test reports.

With extensive cleanroom industry expertise, we are not just a manufacturer, but your Cleanroom Filtration Partner.

Frequently Asked Questions about Cleanroom High-Efficiency Air Filters

Q:What is the filtration principle of a HEPA Air Filter?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

Q: Which standards do your HEPA filters comply with?

A: Our HEPA filters have been tested and certified according to the following international standards:

- EN1822:2019 (European Standard) — H13 to U17 grades

- IEST-RP-CC001 (American Standard)

- ISO 14644-1 (International Cleanroom Standard)

- GB/T 13554 (Chinese National Standard)

Additionally, our production system is certified under the ISO 9001 Quality Management System, and we can provide third-party testing reports (SGS, TÜV, CNAS).

Q: What is the difference between HEPA and ULPA filters?

A: HEPA (High Efficiency) filters capture particles as small as 0.3μm with ≥99.97% efficiency; ULPA (Ultra-Low Penetration Air) filters offer higher efficiency, achieving ≥99.9995% for particles as small as 0.12μm.

Generally:

HEPA is used in pharmaceuticals, healthcare, electronics, food processing, etc..

ULPA is primarily used in semiconductor manufacturing, optoelectronics production, nanoscale cleanrooms, and other ultra-high cleanliness environments.

Q:What is your typical production and delivery lead time?

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.