Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

Soft Wall Cleanroom Solutions

Build your clean environment in a flexible, efficient, and scalable manner.

About Us

As leading Soft Wall Cleanroom Solutions Provider in china, we specialize in delivering efficient, cost-effective, and flexible clean space solutions for the medical device, biotechnology, electronics manufacturing, and precision assembly industries.

With over a decade of cleanroom engineering expertise, we deeply understand the triple demands of modern production environments: stringent cleanliness requirements, rapid scalability, and limited investment budgets.

The Soft Wall Cleanroom (Clean Booth) stands as one of the most competitive solutions in this context. It not only meets ISO 14644-1 Class 5–8 cleanliness standards but also offers exceptional flexibility to adapt to automated production lines, localized operational processes, and rapid deployment requirements.

We deliver not standardized products, but a cleanroom system “custom-designed” to fit your specific process, equipment layout, personnel/material flow, and cleanliness requirements. Whether it’s automated assembly clean enclosures for medical syringes or high-precision packaging zones, we provide stable, verifiable, and scalable soft wall cleanroom solutions.

Explore Our Soft Wall Cleanroom Solutions

Our Soft Wall Cleanroom series delivers rapidly deployable, flexible, and scalable clean production spaces through modular construction and FFU high-efficiency air delivery systems. Whether for automated production lines or localized workstations, we provide ISO-compliant, reliable, and verifiable soft wall cleanroom solutions.

Main types of softwall cleanrooms

|

Types |

Enclosure materials |

Cleanliness classes |

Application scenarios |

Soft curtain type |

PVC transparent soft curtain (ESD protection) | ISO class 7-8 (class 10,000) | Temporary clean area in laboratory, packaging workshop |

|

Mixed type |

PVC soft curtain + tempered glass window | ISO class 6-7 (class 1,000) | Electronic assembly, medical device production |

|

Negative pressure type |

Tempered glass + HEPA exhaust system | ISO 5级(百级) ISO class 5 (class 100) |

Biosafety laboratory, high-activity drug processing |

Soft Wall Cleanroom Solution

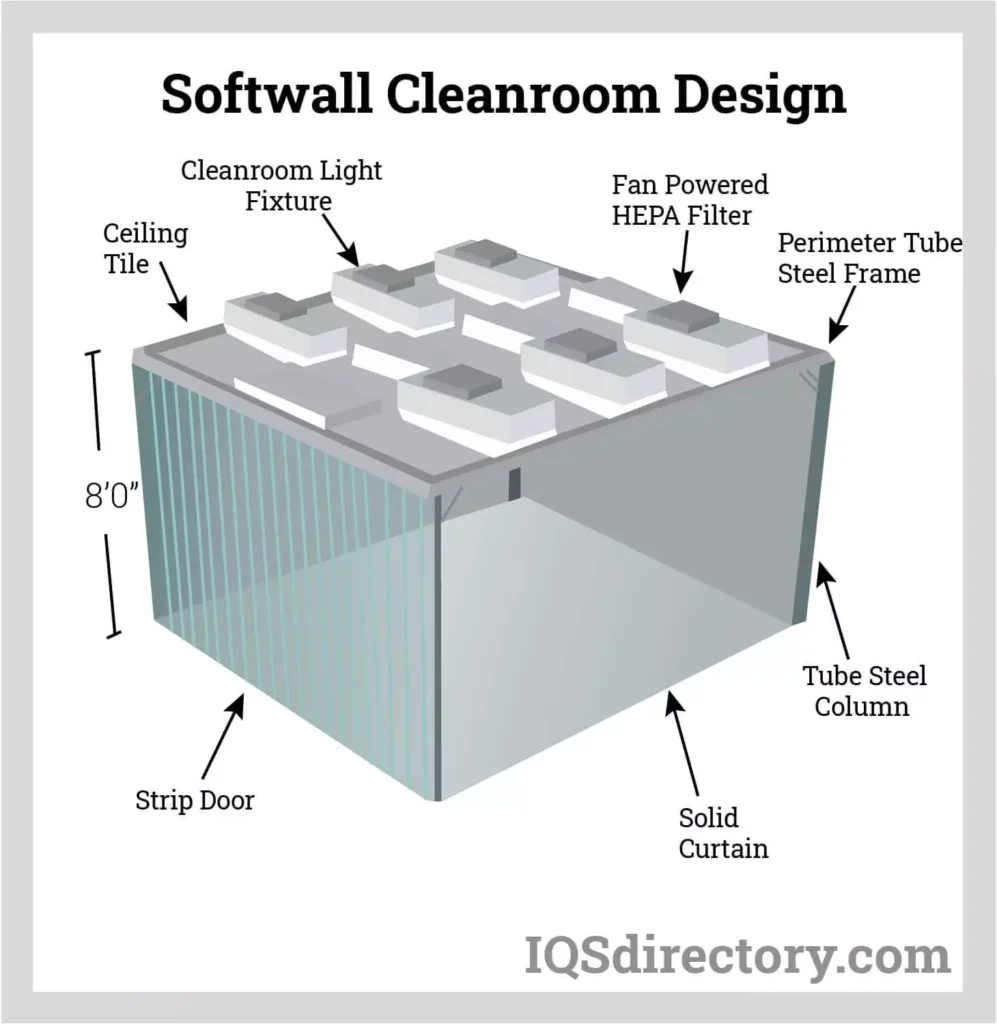

Soft Wall Cleanroom is a movable, modular clean space constructed using an aluminum alloy frame + soft curtain (PVC/ESD transparent soft curtain) + FFU air supply unit.

It continuously supplies HEPA/ULPA-filtered clean air into the interior via overhead FFUs (Fan Filter Units), while utilizing soft curtains to control air pressure and isolate particles, thereby creating a controlled clean environment within the designated area.

The advantages of the Soft Wall Cleanroom include:

– No reliance on walls or building structures

– Rapid setup, expansion, or relocation

– Low maintenance costs

– Flexible adaptation to automated production lines

– Enhanced budget planning flexibility aligned with project timelines

It stands as one of the most cost-effective clean solutions for industrial and medical applications requiring localized clean control.

What are the advantages of softwall cleanrooms?

Fast and efficient: Modular assembly, with a construction period of only a few hours to a few days (1/10 of the time required for traditional cleanrooms).

Low cost: No pre-construction preparation is required, and the cost is only 30%-50% of that of a hardwall cleanroom.

Flexible adjustment: The product can be easily expanded, dismantled, or relocated to accommodate changes in production lines or short-term projects.

Transparent and visible: PVC soft curtain or glass panel facilitates observation of internal operations.

Compliance: The product complies with cleanliness standards such as ISO14644 and GMP.

Custom Soft Wall Cleanroom Solution

Soft Wall Cleanroom is the most flexible and efficient solution for modern clean production.

Soft Wall Cleanroom is more than just a “quickly assembled clean space”; it represents the optimal balance of efficiency, flexibility, and return on investment in today’s manufacturing landscape. Compared to traditional cleanrooms, it delivers a stable, reliable, verifiable, and sustainably operable clean environment at lower costs, faster deployment speeds, and greater scalability. Whether for medical device assembly, automated production lines for medical syringes, or localized clean control in electronics, biotechnology, and precision assembly, it enables enterprises to establish ISO-compliant clean production zones in the shortest time possible without altering existing facility structures.

In today’s era of continuous technological iteration and production line upgrades, Soft Wall Cleanroom delivers not just a temporary solution, but an evolving clean space strategy that adapts to changing demands. Choosing Soft Wall Cleanroom means faster project response, lower operational costs, and greater process adaptability—ensuring your clean environment truly keeps pace with production rhythms and market shifts.

When you require a clean space that delivers “adequate cleanliness, controlled costs, rapid deployment, and seamless scalability,” Soft Wall Cleanroom remains the most strategically advantageous choice.

Core components of softwall cleanroom

Softwall cleanrooms typically adopt aluminum alloy or stainless steel aluminum profiles, which are assembled modularly to form a small clean space. FFUs (fan filter units) are suspended to the ceiling.

The enclosure structure typically adopts a 1.5-2mm anti-static soft curtain; or adopts 5mm acrylic tempered glass to enhance airtightness and observation convenience.

Air cleanliness is controlled by air supply from FFUs installed on the ceiling, with bottom grille air return or side air return.

- LED cleanroom lights are used;

- Optional temperature and humidity sensors and pressure difference sensors can be used to control the start-stop and power of the FFU.

Frequently Asked Questions about Soft Wall Cleanroom Solutions

Is the cleanliness of Soft Wall Cleanrooms reliable? Can they meet ISO standards?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

Is the cleanliness of Soft Wall Cleanrooms reliable? Can they meet ISO standards?

Answer:

Soft Wall structures offer greater flexibility, faster setup, and lower costs, making them particularly suitable for localized workstations or automated production lines. Hard-wall cleanrooms are better suited for large-scale, long-term, fixed clean spaces. Both can be combined as needed based on project requirements.

Can you customize Clean Booths for automated production lines, such as medical syringe assembly lines?

Answer:

Yes. We can design dedicated clean booths tailored to equipment dimensions, process cycle times, and personnel/material flow paths. Features include transparent viewing windows, soft curtain openings, localized laminar flow hoods, and electrical interfaces to create fully customized dust-free work environments.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.