Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

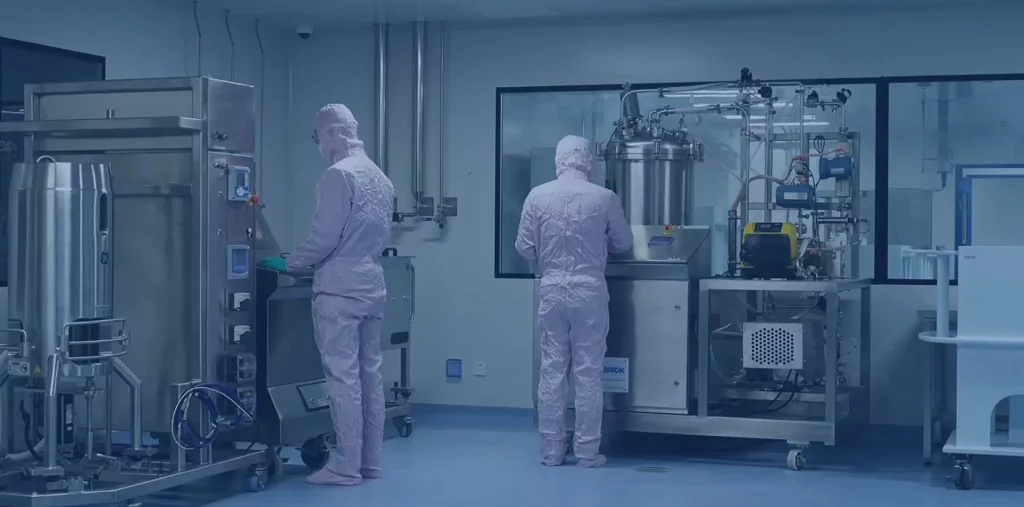

Hard Wall Cleanroom Solutions

—— Creating stable, controllable, and verifiable hard-wall clean spaces for high-standard production environments

About Us

As China’s leading hard wall cleanroom solutions provider, we specialize in creating highly stable, highly controllable hard wall cleanroom systems for the pharmaceutical, food, medical device, biotechnology, electronics manufacturing, and F&B industries that meet ISO 14644, GMP, and FDA requirements.

We deeply understand these industries’ stringent requirements for “cleanliness stability, structural reliability, and strong verifiability.”

Therefore, we not only provide hard wall cleanrooms but also offer full-process technical support from design and manufacturing to installation and validation.

Our hardwall systems have been successfully deployed in:

- Pharmaceutical production facilities (OSD, sterile preparations, APIs)

Medical device assembly and packaging areas - Sterile processing and filling zones in food and beverage plants.

- Precision electronics manufacturing, modular factories, and clean packaging.

- Laboratories and testing institutions

For every project, our goal is to deliver a cleanroom space that is auditable, traceable, and sustainably operable.

Our Cleanroom HEPA Air Filter Product Range

We provide a complete clean air filtration system ranging from primary to ultra-high efficiency filtration. Our solutions serve multiple industries including electronics, pharmaceuticals, biotechnology, healthcare, and food processing.

Cleanliness class and configuration reference

| ISO class | Class Corresponding class | Airflow mode | Recommended configuration |

| ISO 5 | Class 100 | Unidirectional flow (vertical/horizontal) | 100% FFU coverage + raised floor |

| ISO 7 | Class 10,000 | Non-unidirectional flow | High-efficiency air supply outlet + 30%-50% ceiling coverage rate |

| ISO 8 | Class 100,000 | Non-unidirectional flow | High-efficiency air supply outlet + local FFU air supplement |

What is a hardwall modular cleanroom?

Hardwall modular cleanroom is a clean space of which the core functions such as enclosure structure, air purification, airflow organization, and control system are disassembled into standardized modules, and these modules are transported to the site for rapid assembly after prefabrication in the factory. Its core objective is to address issues such as long construction period, poor flexibility, and unstable quality in traditional cleanroom construction through the “modular design + industrial production” mode.

Core characteristics and advantages of hardwall modular cleanrooms

- Fast and efficient: Prefabricated components are assembled on-site, reducing the construction period by 50%-70% compared to traditional cleanrooms.

- Flexible expansion: the product supports modular expansion in both horizontal (area) and longitudinal (function) directions, adapting to production line adjustments.

- Cost controllable: the product reduces initial investment and subsequent renovation costs.

- Intelligent integration: the product can be embedded into intelligent management such as EMS (Environmental Monitoring System) and FFU group control.

- Compliance: the product meets international standards such as GMP, ISO 14644, and FDA.

Core component modules

Wallboard/ceiling board: the product adopts high-quality color steel plates, and is modularly assembled; material thickness: 50-100mm (sound insulation, thermal insulation).

Doors and windows: the product adopts cleanroom doors and double-glazed observation windows (dust-proof).

Flooring: PVC rolls (wear-resistant), raised floor (underfloor air supply)

Air supply system: FFU (fan filter unit): HEPA H13-H14 grade, covering the ceiling or side walls. High-efficiency air supply outlet: used in conjunction with the air conditioning system for centralized air supply.

Airflow organization: Unidirectional flow (vertical/horizontal): ISO class 5 (class 100). Non-unidirectional flow: ISO class 7-8 (class 10,000-100,000).

Air conditioning and temperature control: constant temperature and humidity unit (accuracy ±1℃), adjustable fresh air ratio.

Lighting: LED cleanroom light (recessed, no dust accumulation dead corners).

Monitoring: Real-time monitoring of temperature and humidity, pressure difference, and particle counting (networked alarm).

Pipeline integration: Concealed layout of water, electricity, gas lines, and data cables.

Frequently Asked Questions about Hard Wall Cleanroom Solutions

Aseptic preparation filling line (grade A area), GMP workshop.

chip lithography room, microelectronic assembly (ESD protection).

Stem cell laboratory, PCR testing room.

aseptic packaging workshop, probiotic fermentation area.

nanomaterial research and development, precision instrument testing.

Construction process

Demand analysis: Determine parameters such as cleanliness class, area, temperature, and humidity.

Module design: 3D modeling to simulate airflow and optimize component layout.

Factory prefabrication: Pre-assembly of wall panels, pipelines, etc., to reduce on-site construction.

On-site installation: assembly of structure → installation of clean system → commissioning and testing.

Acceptance testing: PAO leak detection, particle counting, and pressure difference verification.

Frequently Asked Questions about Hard Wall Cleanroom Solutions

What is the difference between Hard Wall Cleanrooms and Soft Wall Cleanrooms?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

What cleanliness levels can your hardwall cleanrooms achieve?

Answer:

We can build ISO Class 5–8 cleanroom systems tailored to customer requirements, incorporating HEPA/ULPA filtration, differential pressure control, temperature and humidity regulation, and airflow organization design to ensure consistently stable and verifiable cleanliness.

What materials are used for hard wall cleanrooms? How to choose?

Answer:

We offer:

- Steel panels (color-coated steel/steel cleanroom panels): Durable, suitable for pharmaceutical facilities

- Glass hard walls (double-layered tempered glass): Aesthetic, scratch-resistant, suitable for food and biological laboratories

- Acrylic panels: Lightweight and transparent, suitable for clean booths or local clean zones

Material selection should be determined based on industry regulations, cleanability, corrosion resistance, and visibility requirements.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.