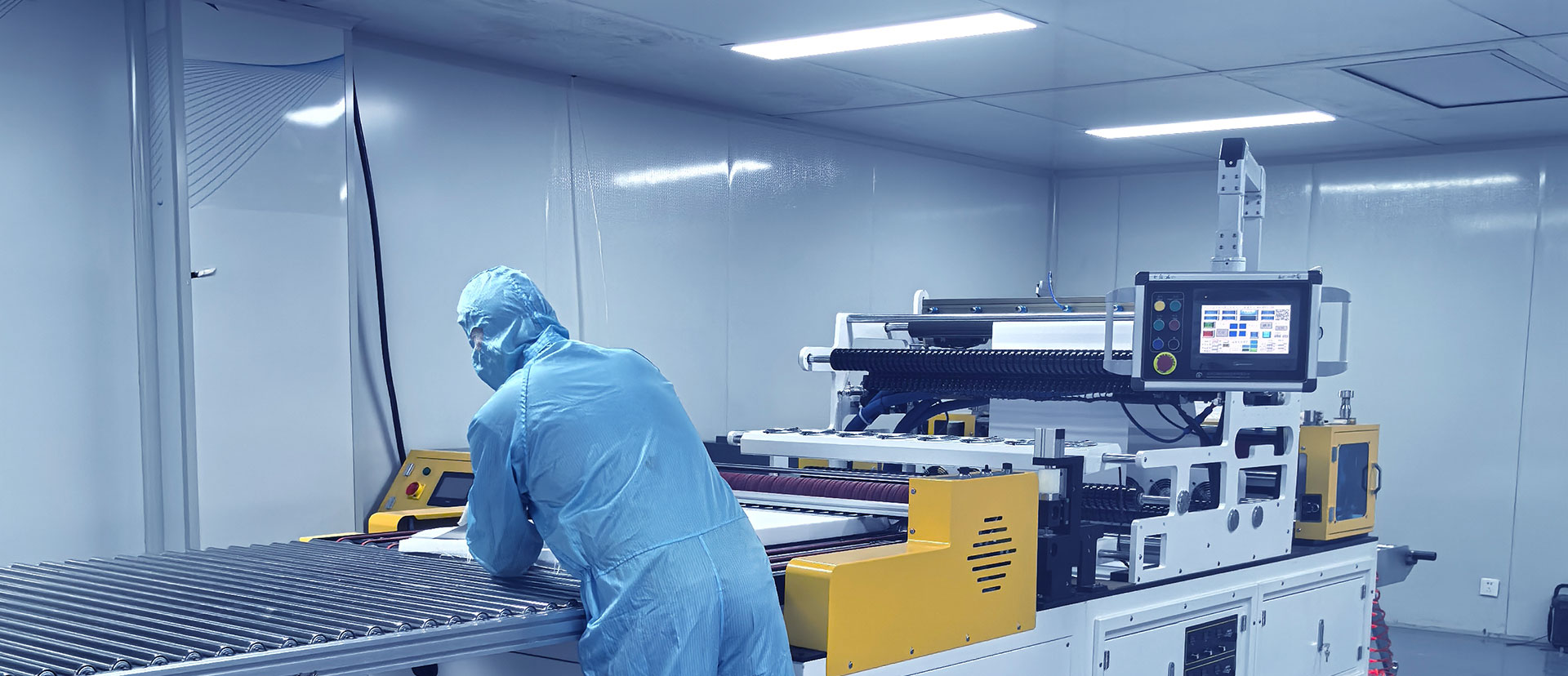

Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

HEPA Box for pharmaceutical

An HEPA air inlet is an ideal terminal filtration device for Class 1,000, 10,000, and 100,000 cleanroom air conditioning systems. It is widely used in cleanroom air conditioning systems in the pharmaceutical, health, electronics, and chemical industries.

Table of Contents

What is aHEPA air inlet

An HEPA air inlet is a specialized accessory device for installing a high-efficiency filter at the end of a purification system.

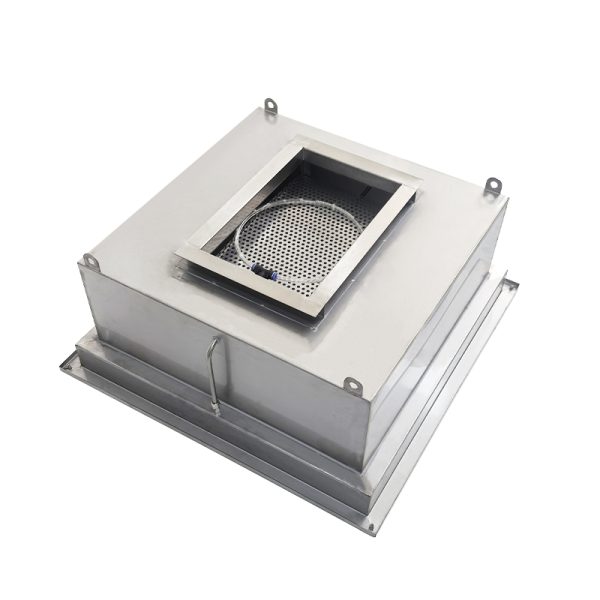

An HEPA air inlet is an ideal terminal filtration device for Class 1,000, 10,000, and 100,000 cleanroom air conditioning systems. It is widely used in cleanroom air conditioning systems in the pharmaceutical, health, electronics, and chemical industries. It is used as a terminal filtration device for the renovation and construction of cleanrooms ranging from Class 1,000 to Class 300,000, and is a key component in meeting purification requirements. An HEPA air inlet includes a static pressure box, diffuser, and HEPA filter. It can be connected to the air duct from the top or side.

Core Functions and Features of HEPAair inlet

- High-efficiency filtration: Built-in H13-H14 HEPA or U15 ULPA filters, filtration efficiency ≥995% @ 0.3μm.

- Uniform air delivery: Equipped with a flow-balancing membrane or diffuser, air velocity uniformity deviation ≤±15%.

- Low-resistance design: Optimized structure reduces pressure drop (initial resistance ≤150Pa).

- Flexible installation: Can be embedded in the ceiling, side wall, or bracket-mounted, adapting to different cleanroom systems.

- Intelligent control (optional): Pressure differential monitoring, air volume adjustment, and remote alarm functions.

Main types of HEPA air inlet

| Type | Features | Application |

| Top supply type | Ceiling installation, vertical downward air supply, large coverage area | Clean rooms, operating rooms, electronics factories |

| Side supply type | Wall installation, horizontal air supply, suitable for spaces with limited floor height | Laboratories, isolation wards |

| With diffuser plate type | Install a multi-hole flow plate to make the wind speed more uniform (0.35-0.5m/s) | Unidirectional flow clean area (such as Class A filling line) |

| Adjustable air volume type | Equipped with Venturi valve or electric air valve to adjust the air volume in real time | Variable Air Volume (VAV) |

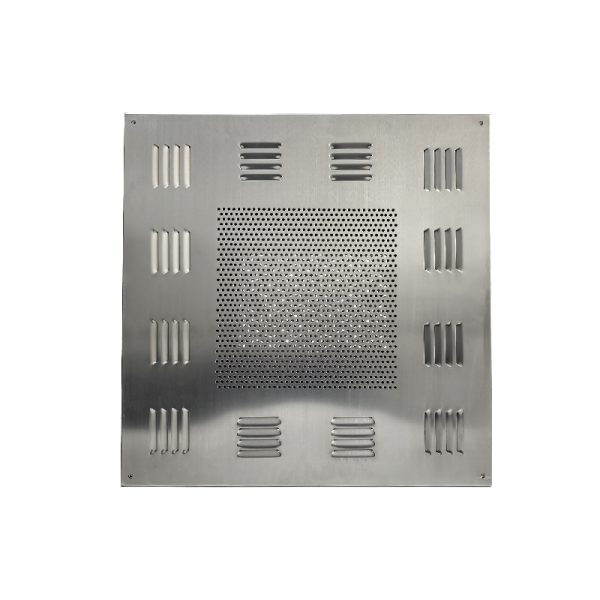

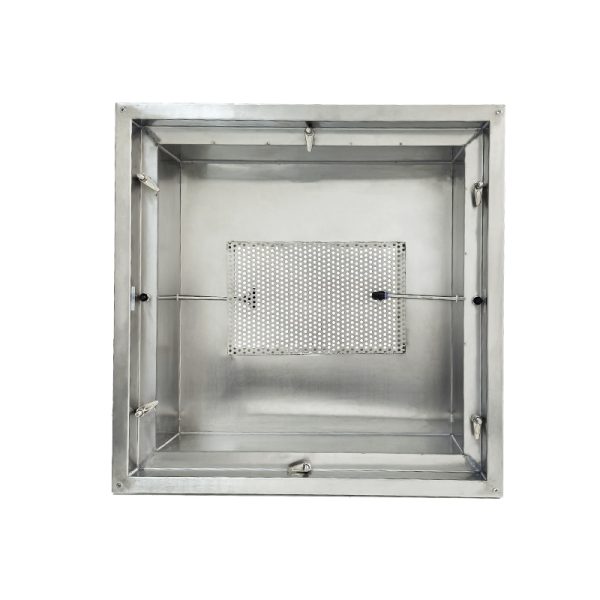

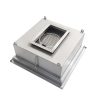

Core Structure and Operating Principle of the HEPA filter box

Structural Components

- Case:

Material: 304 stainless steel (corrosion-resistant), galvanized steel (economical).

Seal: Polyurethane foam or silicone strips to prevent leaks (PAO leak detection ≤ 0.01%).

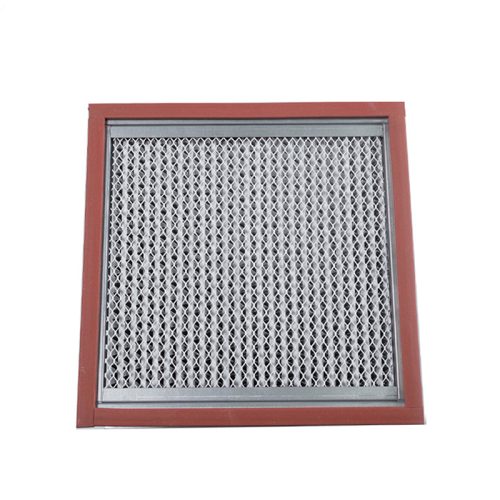

- Filter:

HEPA H13-H14 or ULPA U15 (reduces resistance).

- Flow Equalization Device:

Flow-equalizing membrane (aluminum foil/nylon mesh) or porous diffuser to ensure even air distribution.

- Accessories:

Flange interface (for connection to duct), differential pressure gauge, and inspection light (optional).

Operating Principle

- Air Filtration:Air from the air conditioning system is filtered through a HEPA filter to remove particulate matter.

- Flow Equalization: A diffuser adjusts the airflow direction to create a stable laminar flow.

- Cleanliness Maintenance:Continuously delivers clean air, diluting and discharging pollutants.

Application Areas of HEPA filter

- Pharmaceutical Industry: Class A cleanrooms (filling lines), Class B background areas.

- Electronics Manufacturing: Chip lithography workshops (Class 10), LCD cleanrooms.

- Medical Industry: Operating rooms, PCR laboratories, negative pressure isolation wards.

- Food Industry: Aseptic packaging workshops, cleanrooms around fermentation tanks.

Installation and Maintenance of HEPA filter box

- After connecting the duct, perform a leak test (PAO/DOP test).

- Install the filter and tighten the seal.

- Adjust the air volume and uniformity (using an anemometer).

Maintenance Requirements:

- Monthly check the pressure differential (replace the filter if it is ≥2 times the initial value).

- Perform a full leak test and clean the interior of the cabinet annually.

Difference betweenHEPA filter box and ordinary filter box

| Comparison Items | HEPA air inlet | Ordinary air inlet |

| Filtration efficiency | H13-H14 grade (≥99.95%@0.3μm) | No filtration or primary filtration (G4 grade) |

| Airflow organization | Laminar flow, uniform wind speed | Turbulence, uneven wind speed |

| Cleanliness level | Up to ISO Class 5 (Class 100) | Only suitable for normal air-conditioned areas |

| Cost | Higher (including HEPA and flow-balanced design) | Low |