Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

Hard Wall Acrylic Board Clean Booth for pharmaceutical/food/medical industry

Table of Contents

What is a hardwall modular cleanroom?

Hardwall modular cleanroom is a clean space of which the core functions such as enclosure structure, air purification, airflow organization, and control system are disassembled into standardized modules, and these modules are transported to the site for rapid assembly after prefabrication in the factory. Its core objective is to address issues such as long construction period, poor flexibility, and unstable quality in traditional cleanroom construction through the “modular design + industrial production” mode.

Core characteristics and advantages of hardwall modular cleanrooms

Fast and efficient: Prefabricated components are assembled on-site, reducing the construction period by 50%-70% compared to traditional cleanrooms.

Flexible expansion: the product supports modular expansion in both horizontal (area) and longitudinal (function) directions, adapting to production line adjustments.

Cost controllable: the product reduces initial investment and subsequent renovation costs.

Intelligent integration: the product can be embedded into intelligent management such as EMS (Environmental Monitoring System) and FFU group control.

Compliance: the product meets international standards such as GMP, ISO 14644, and FDA.

Core component modules

Structural module

Wallboard/ceiling board: the product adopts high-quality color steel plates, and is modularly assembled; material thickness: 50-100mm (sound insulation, thermal insulation).

Doors and windows: the product adopts cleanroom doors and double-glazed observation windows (dust-proof).

Flooring: PVC rolls (wear-resistant), raised floor (underfloor air supply)

Clean system module

Air supply system: FFU (fan filter unit): HEPA H13-H14 grade, covering the ceiling or side walls. High-efficiency air supply outlet: used in conjunction with the air conditioning system for centralized air supply.

Airflow organization: Unidirectional flow (vertical/horizontal): ISO class 5 (class 100). Non-unidirectional flow: ISO class 7-8 (class 10,000-100,000).

Air conditioning and temperature control: constant temperature and humidity unit (accuracy ±1℃), adjustable fresh air ratio.

Auxiliary system

Lighting: LED cleanroom light (recessed, no dust accumulation dead corners).

Monitoring: Real-time monitoring of temperature and humidity, pressure difference, and particle counting (networked alarm).

Pipeline integration: Concealed layout of water, electricity, gas lines, and data cables.

Cleanliness class and configuration reference

| ISO class | Class Corresponding class | Airflow mode | Recommended configuration |

| ISO 5 | Class 100 | Unidirectional flow (vertical/horizontal) | 100% FFU coverage + raised floor |

| ISO 7 | Class 10,000 | Non-unidirectional flow | High-efficiency air supply outlet + 30%-50% ceiling coverage rate |

| ISO 8 | Class 100,000 | Non-unidirectional flow | High-efficiency air supply outlet + local FFU air supplement |

Typical application scenarios

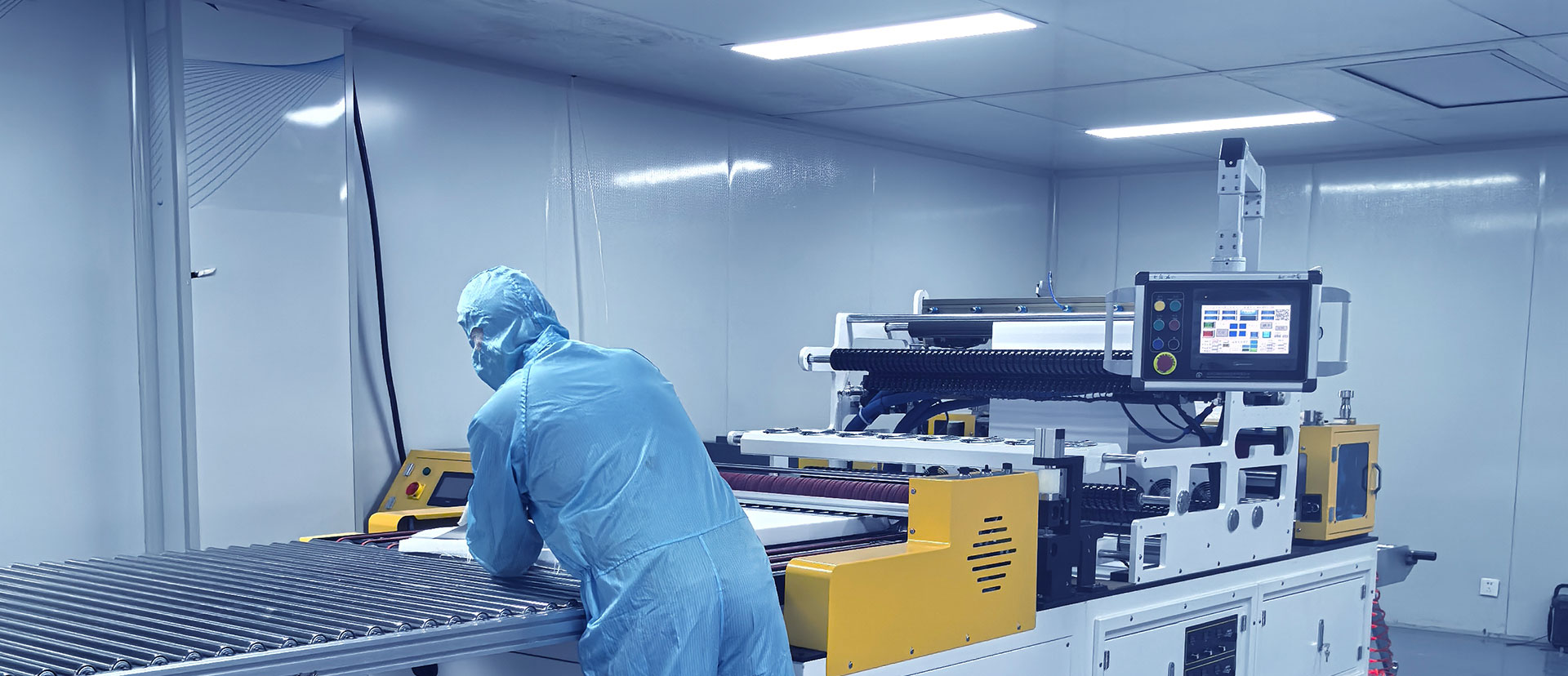

Pharmaceutical industry: Aseptic preparation filling line (grade A area), GMP workshop.

Electronic manufacturing: chip lithography room, microelectronic assembly (ESD protection).

Medical field: Stem cell laboratory, PCR testing room.

Food industry: aseptic packaging workshop, probiotic fermentation area.

Scientific research institutions: nanomaterial research and development, precision instrument testing.

Construction process

Demand analysis: Determine parameters such as cleanliness class, area, temperature, and humidity.

Module design: 3D modeling to simulate airflow and optimize component layout.

Factory prefabrication: Pre-assembly of wall panels, pipelines, etc., to reduce on-site construction.

On-site installation: assembly of structure → installation of clean system → commissioning and testing.

Acceptance testing: PAO leak detection, particle counting, and pressure difference verification.

Reference for cleanliness and spatial layout

7.1 ISO class 5 (class 100) unidirectional flow cleanrooms: FFU coverage rate: 80%-100% (full ceiling coverage).

7.2 ISO class 7 (class 10,000) non-unidirectional flow cleanrooms; FFU coverage rate adjusted according to air change rate.

7.3 The height of unidirectional flow cleanrooms should be ≥2.6m (including the installation space for FFU); non-unidirectional flow cleanrooms can have a lower height (2.4m-2.8m)

7.4Air ducts/electrical circuits adopt a modular quick-connection design