Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

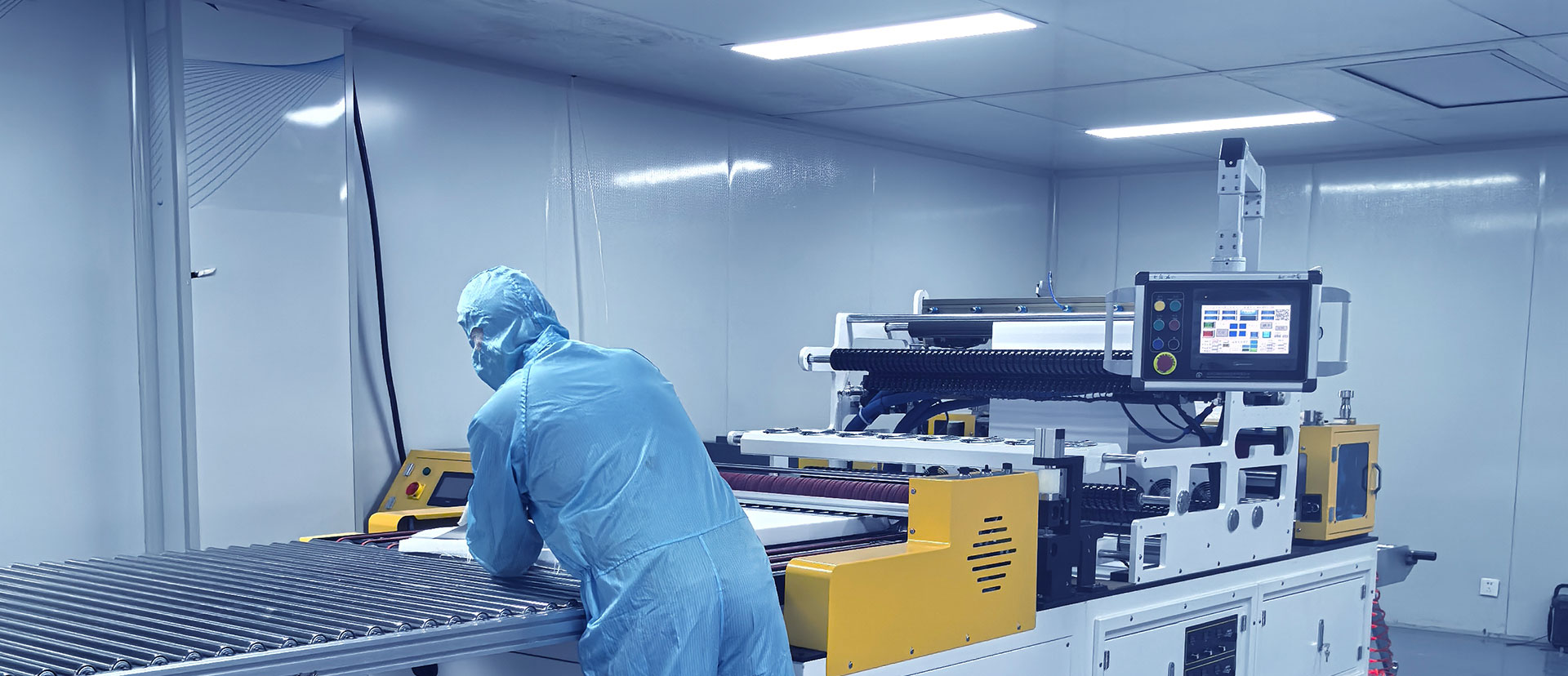

Medical Syringe Automation Assembly Line Clean Booth

It features characteristics such as rapid installation, low cost, and flexible adjustment, and is suitable for small areas with moderate cleanliness requirements (ISO class 5-8).

Table of Contents

What is a softwall cleanroom?

The softwall cleanroom is a modular clean environment constructed using soft enclosures (such as PVC soft curtains and tempered glass partitions). It features characteristics such as rapid installation, low cost, and flexible adjustment, and is suitable for small areas with moderate cleanliness requirements (ISO class 5-8).

What are the advantages of softwall cleanrooms?

Fast and efficient: Modular assembly, with a construction period of only a few hours to a few days (1/10 of the time required for traditional cleanrooms).

Low cost: No pre-construction preparation is required, and the cost is only 30%-50% of that of a hardwall cleanroom.

Flexible adjustment: The product can be easily expanded, dismantled, or relocated to accommodate changes in production lines or short-term projects.

Transparent and visible: PVC soft curtain or glass panel facilitates observation of internal operations.

Compliance: The product complies with cleanliness standards such as ISO14644 and GMP.

Main types of softwall cleanrooms

|

Types |

Enclosure materials |

Cleanliness classes |

Application scenarios |

|

Soft curtain type |

PVC transparent soft curtain (ESD protection) | ISO class 7-8 (class 10,000) | Temporary clean area in laboratory, packaging workshop |

|

Mixed type |

PVC soft curtain + tempered glass window | ISO class 6-7 (class 1,000) | Electronic assembly, medical device production |

|

Negative pressure type |

Tempered glass + HEPA exhaust system | ISO 5级(百级)

ISO class 5 (class 100) |

Biosafety laboratory, high-activity drug processing |

Core components of softwall cleanroom

Framework

Softwall cleanrooms typically adopt aluminum alloy or stainless steel aluminum profiles, which are assembled modularly to form a small clean space. FFUs (fan filter units) are suspended to the ceiling.

Enclosure

The enclosure structure typically adopts a 1.5-2mm anti-static soft curtain; or adopts 5mm acrylic tempered glass to enhance airtightness and observation convenience.

Airflow organization:

Air cleanliness is controlled by air supply from FFUs installed on the ceiling, with bottom grille air return or side air return.

Auxiliary facilities

- LED cleanroom lights are used;

- Optional temperature and humidity sensors and pressure difference sensors can be used to control the start-stop and power of the FFU.

What aspects should be considered in the construction of softwall cleanrooms?

- Provide electronic drawings of the existing site

- Understand the dimensions and cleanliness class of the softwall cleanroom required in the project

- Provide on-site photos for design reference.