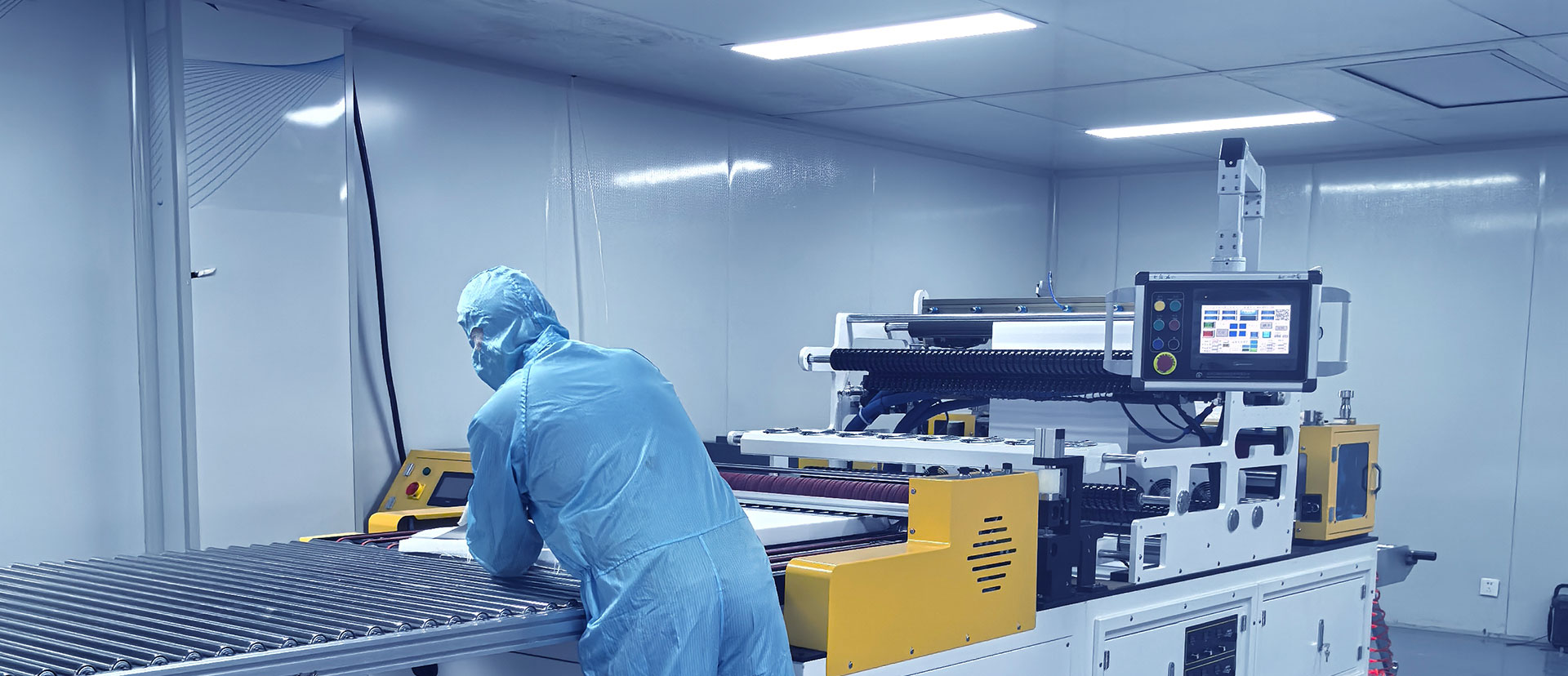

Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

Aseptic isolators

Aseptic isolators are used for sterile production and testing, meet Class A clean standards, use stainless steel/tempered glass hard cabins, and have laminar or turbulent flow designs.

Table of Contents

What is a sterile isolator?

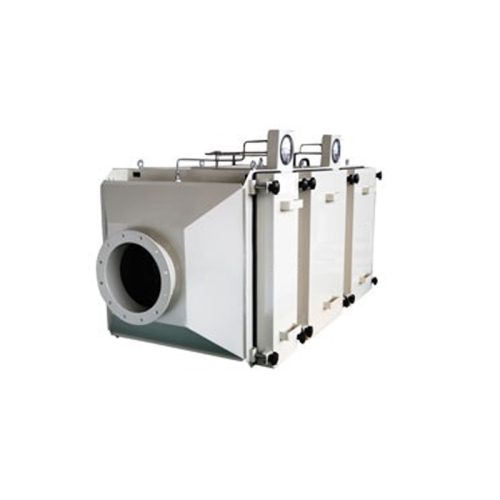

Isolators are mainly used in the pharmaceutical industry to provide a physical barrier to protect the sterile environment and personnel safety. It consists of an operating cabin and a transfer cabin, with a positive pressure fully enclosed design. The airflow pattern is similar to that of a biological safety cabinet, but the pressure is opposite. It supports processes such as filling, weighing, and batching, and can be customized in size and equipped with an optional VHP sterilization system. Aseptic isolators are used for sterile production and testing, meet Class A clean standards, use stainless steel/tempered glass hard cabins, and have laminar or turbulent flow designs. **The closed isolator completely isolates personnel and processes to prevent contamination, and is suitable for sterile inspections, microbial testing, etc. Operations are performed using gloves, and materials enter and exit the transfer cabin.

What are the characteristics of sterile isolators?

1、VHP sterilization: Dry vaporized hydrogen peroxide (6-log spore killing), concentration monitoring, residual <1ppm, GMP A-level cleanliness after sterilization

2、Sealing performance: 2 times pressure test leakage rate <0.5%/h, support -80Pa~80Pa adjustable (conventional 40Pa~60Pa), positive/negative pressure mode can be preset

3、Compliance design: compliant with GMP, 2015 Pharmacopoeia, USP/EP, support 21CFR part11 electronic records, gas source is 0.6~0.8MPa clean air/nitrogen

4、Cleanliness monitoring: manual no-dead-angle cleaning, optional online particle/floating bacteria detection system

- 无菌隔离器的技术核心是什么?

What is the technical core of a sterile isolator?

Fully enclosed operation (glove/half-body operation interface)

Integrated VHP sterilization (log reduction ≥ 6)

Negative /Positive pressure adjustable (adaptable to different risk materials)

What are the application scenarios of sterile isolators?

Vaccine aseptic filling

Requirement:

Ensure the sterility of the mRNA vaccine filling process in compliance with FDA/EMA regulations.

Solution:

Fully automated isolator with integrated VHP sterilization (log6 microbial kill). Equipped with Class A laminar flow (ISO Class 5) and online particle monitoring system.

Result:

Achieved zero-contamination batch production and passed FDA on-site audit.

Filling efficiency increased by 30% (compared to traditional RABS system).

Cell therapy product preparation

Requirement:

Sterility and cross-contamination prevention and control of CAR-T cell processing.

Solution:

Solution:Small biosafety isolator (BSL-2 level) with integrated CO₂ culture module.

Single-person mobile design saves clean room space.

Result:

The contamination rate of cell products has been reduced from 5% to 0.2%.

50 clinical-grade cell preparations have been successfully completed.

常见尺寸?