Boben | Global Leader in Cleanroom Equipment& HEPA Filtration

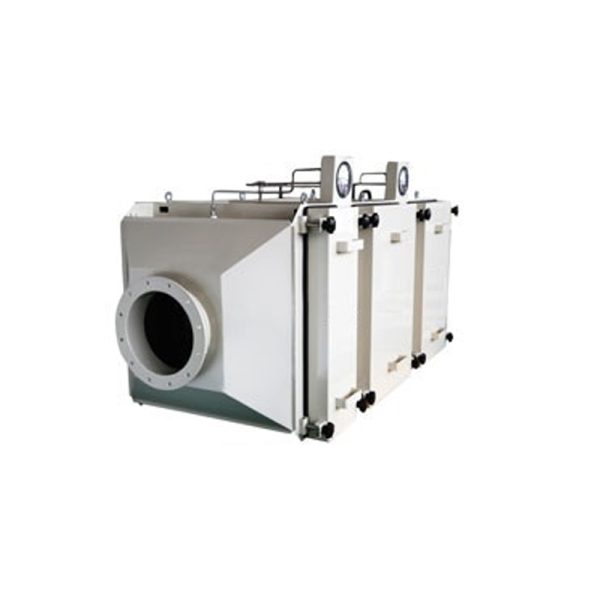

bag in bag out filter

The bag-in-bag-out filter box effectively prevents secondary air pollution and ensures the safety of operators.

Table of Contents

What is a bag in and out filter?

The bag-in-bag-out filter box adopts a fully enclosed bag-in-bag-out design, which can effectively isolate the contamination of radioactive gases, pathogens and chemicals. The bag-in-bag-out filter box effectively prevents secondary air pollution and ensures the safety of operators.

What are the technical characteristics of filters?

- The fully enclosed design can isolate radioactive gases, pathogens and toxic chemicals, prevent secondary pollution and ensure personnel safety. It is suitable for medical, pharmaceutical, nuclear industry, biochemical laboratories and other fields. It is divided into single-effect (high-efficiency filtration) and multiple-effect filtration systems (primary effect, chemical, activated carbon and other filtration sections can be superimposed).

- Modular design, compact structure, can be stacked in 3 layers, saving space. The box body is made of 304 stainless steel or cold-rolled steel (electrostatic spraying), with a pressure resistance of 2500Pa (positive pressure)/3000Pa (negative pressure). Quick pressure filter replacement, easy and reliable operation. Optional large air volume or PTFE high-efficiency filter (U16 grade), air volume up to 4000CMH, impact resistance and damage resistance.

What are the application scenarios of bag in and out filters?

OEB4/OEB5 Pharmaceutical workshop

Requirement:

High-level OEB environmental air mixing system with high efficiency, the accumulated active/toxic substances in the device have a very high risk of causing disease.

Solution:

Non-contact replacement is highly efficient, avoiding personnel contact with high-risk substances. Close the front and rear valves for static operation.

Result:

Isolate risks by standardizing SOPs and combining excellent equipment performance.

P3/P4 Biological Laboratory

Solution:

Negative pressure BIBO+VHP sterilization, sterilization capacity LOG6;Efficient replacement of isolation bags to avoid exposure to air

Result:

The risk of infection for waste disposal workers has been reduced to 0,A key bonus for obtaining CNAS laboratory certification.

Conventional size specification table

| Model | BO-211 | BO-212 | BO-213 |

| Outer size (H*W*D) | 708*403*540mm | 708*708*794mm | 1416*1416*1694 |

| Max flow | 1700CMH/1000CFM | 3400CMH/2000CFM | 13600CMH/8000CFM |

| HEPA function segment | H14(EN1822) | H14(EN1822) | H14(EN1822) |

| HEPA size | 610*305*292mm | 610*610*292mm | 610*610*292mm |

| Box material | N/A | N/A | N/A |

| PAO Sampling port | SUS304 | ||

| Differential pressure gauge/sensor | SUS304 | ||

| Instrument protection system | Optional 0-500Pa | ||

| Biological containment valve | Optional | ||

| Disinfection port | Optional | ||

| HEPA PAO scanning section | Optional | ||

What are the advantages of our bag in bag out filter??

Adopting self-developed modular functional technology

Protecting personnel and the environment from high risk of exposure to hazardous substances by contactless filter replacement via sealed bags

1、Staggered seal bag replacement system,Independent screw drive,Liquid tank high efficiency filte

2、Manual/automatic online scanning system,Universal sterilization interface

3、No mechanical penetration design, leakage rate <0.005%, the lowest in the industry.